Table of Contents

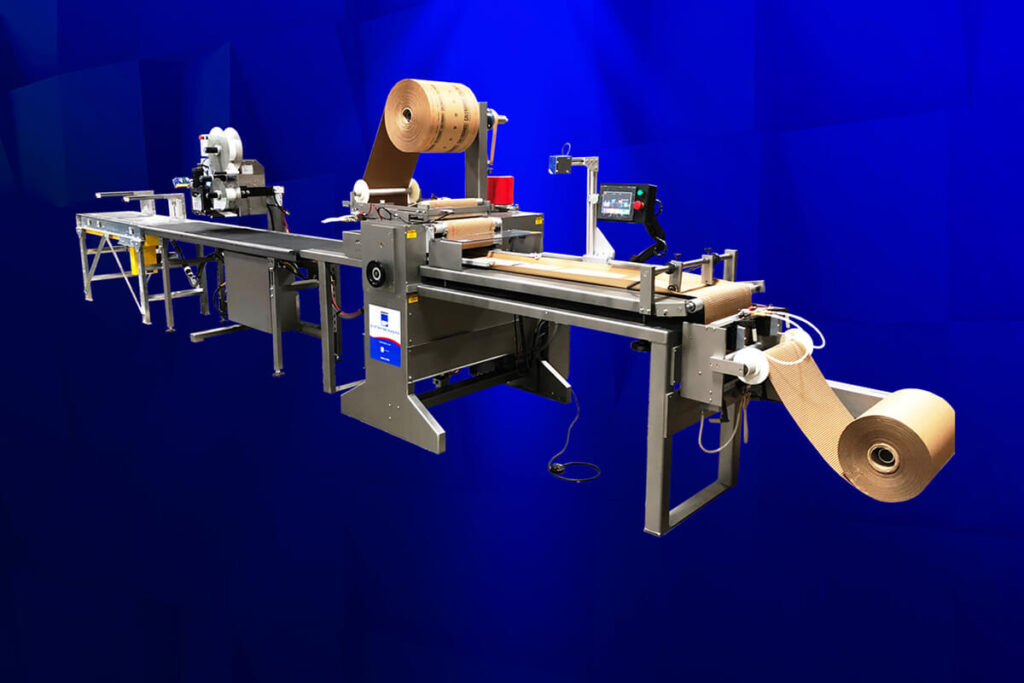

Efficiency, accuracy, and scalability are essential for manufacturers and fulfillment centers aiming to improve their packaging processes. Many businesses are turning to automated packaging systems to replace manual labor, increase throughput, and reduce operational costs. These systems offer a practical, long-term solution for companies looking to optimize production while maintaining consistent quality.

Upgrading to automated packaging machines delivers significant benefits across the packaging production line. Below are five key advantages of making the switch.

1. Increased Efficiency and Throughput

Switching to automated packaging systems allows for exponentially faster processing speeds compared to manual labor or outdated equipment. These systems can operate around the clock, minimize idle time, and keep up with high production demands without compromising on quality.

System Packaging’s cold seal and heat seal machinery, as well as our vertical form, fill, and seal machines, are engineered to increase packaging line output exponentially while maintaining precision. The result is more consistent production and the ability to scale operations without expanding labor resources.

2. Reduced Labor Costs and Operational Expenses

Labor shortages and rising wages have become a persistent concern for many businesses. Investing in automated packaging equipment helps address these challenges by reducing dependency on manual labor and lowering the risk of human error. Automation not only minimizes repetitive tasks but also reduces waste and rework caused by packaging inconsistencies. Over time, the cost savings from fewer errors, less downtime, and reduced material waste contribute directly to the bottom line.

3. Improved Accuracy and Product Protection

Precision is essential when packaging sensitive or high-value items. Automated packaging machines offer greater consistency in seal strength, alignment, and material usage, ensuring every package meets your quality standards. System Packaging’s solutions are designed to support industries like e-commerce, electronics, and retail, where product presentation and protection are non-negotiable. By automating the process, businesses can maintain uniformity across every unit packaged, no matter the shift or operator.

4. Greater Scalability and Flexibility

One of the biggest advantages of automated packaging systems is their adaptability to changing business needs. As order volumes grow, these machines can easily be adjusted or upgraded to handle new packaging formats, materials, or product sizes. System Packaging builds equipment that supports scalability from the outset. Our engineering team works closely with customers to ensure systems can evolve with their operations. Modular designs and customization options provide long-term value and flexibility without constant reinvestment.

5. Enhanced Data and System Integration

Modern automated packaging equipment is often integrated with software systems that provide real-time production data, diagnostics, and reporting. This connectivity enables better decision-making, predictive maintenance, and streamlined inventory management. By pairing packaging machines with smart controls or ERP systems, businesses gain visibility into the full packaging lifecycle. That insight leads to better planning, fewer disruptions, and a stronger return on investment.

FAQs About Automated Packaging Systems

Before committing to new equipment, stakeholders often have questions about implementation, ROI, and long-term performance. Here are some common questions companies ask when considering automation for their packaging process.

What types of businesses benefit most from automated packaging systems?

Industries such as e-commerce, retail, electronics, food processing, and industrial manufacturing often see the greatest ROI from automation due to high throughput requirements and the need for consistency.

How quickly can automated packaging machines start delivering ROI?

Many businesses begin seeing returns within the first year, especially when factoring in reduced labor costs, increased output, and fewer errors. System Packaging machines are designed for long-term performance with minimal downtime.

Can automated systems handle custom packaging formats?

Yes. System Packaging offers customizable machines built to suit specific product dimensions, materials, and sealing requirements. Our engineering team collaborates with each customer to tailor solutions that fit their workflow.

What support is available after purchase?

System Packaging provides full support, including installation, training, replacement parts, and ongoing service. Our team is based in Perrysburg, Ohio, with capabilities for rapid response and maintenance.

Take the Next Step Toward Smarter Packaging

If you’re ready to reduce labor costs, increase accuracy, and build a more scalable packaging operation, System Packaging is here to help. With over 50 years of experience and a full line of automated packaging systems, we deliver solutions tailored to your production goals.

Contact our team today to discuss your packaging challenges and explore how our American-made equipment can support your next phase of growth. Visit our Services and Parts page to learn more about how we can help you maintain peak production efficiency.