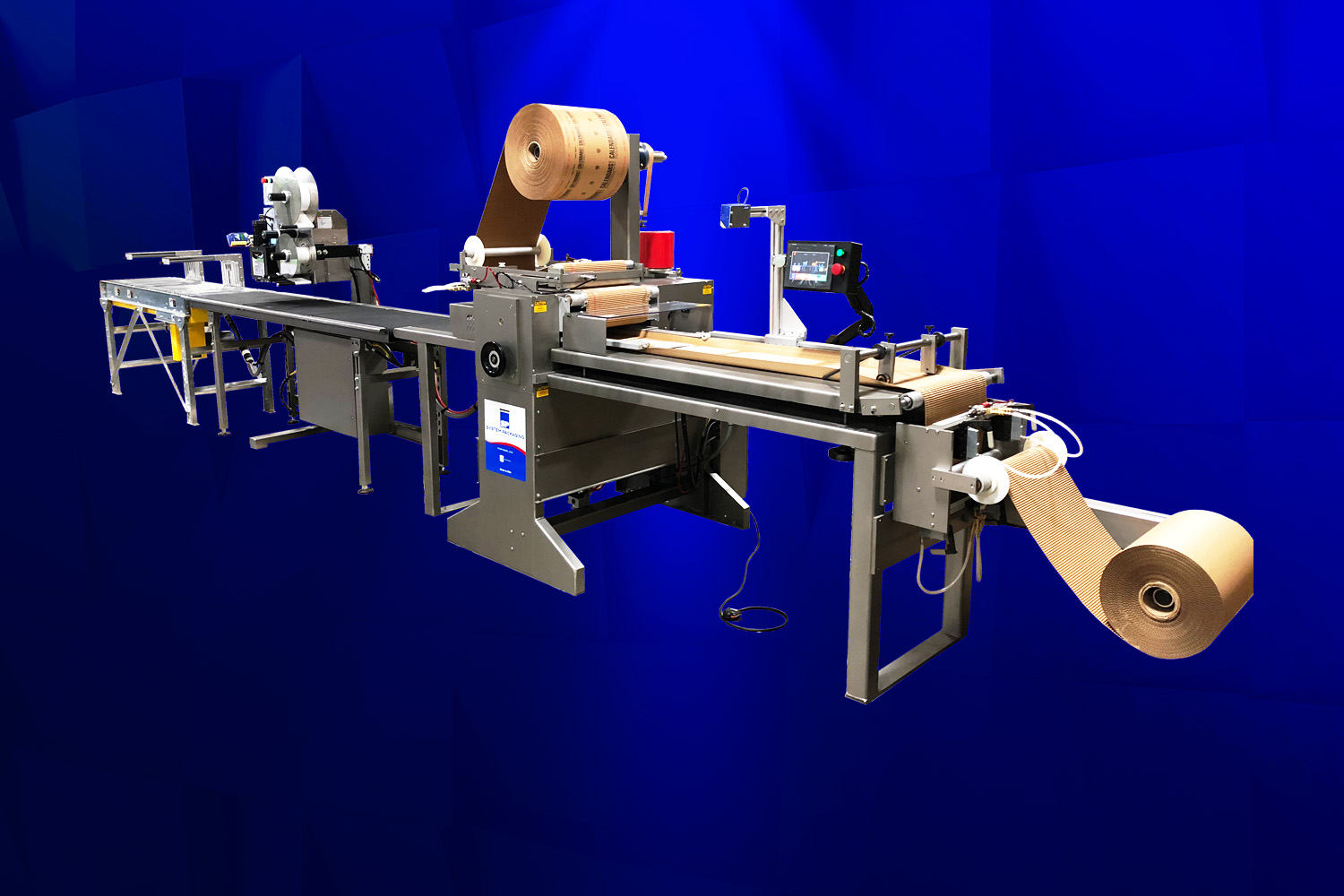

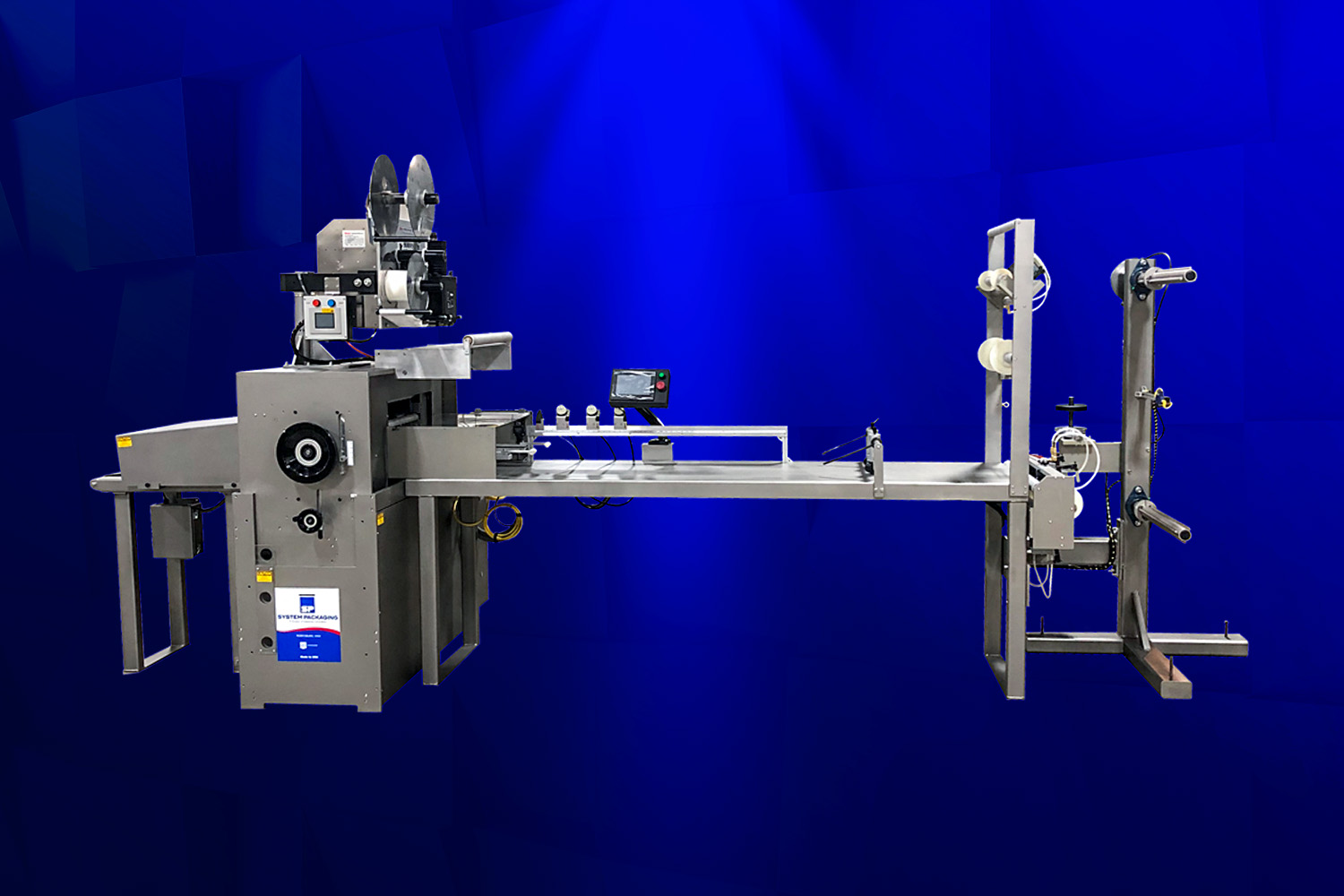

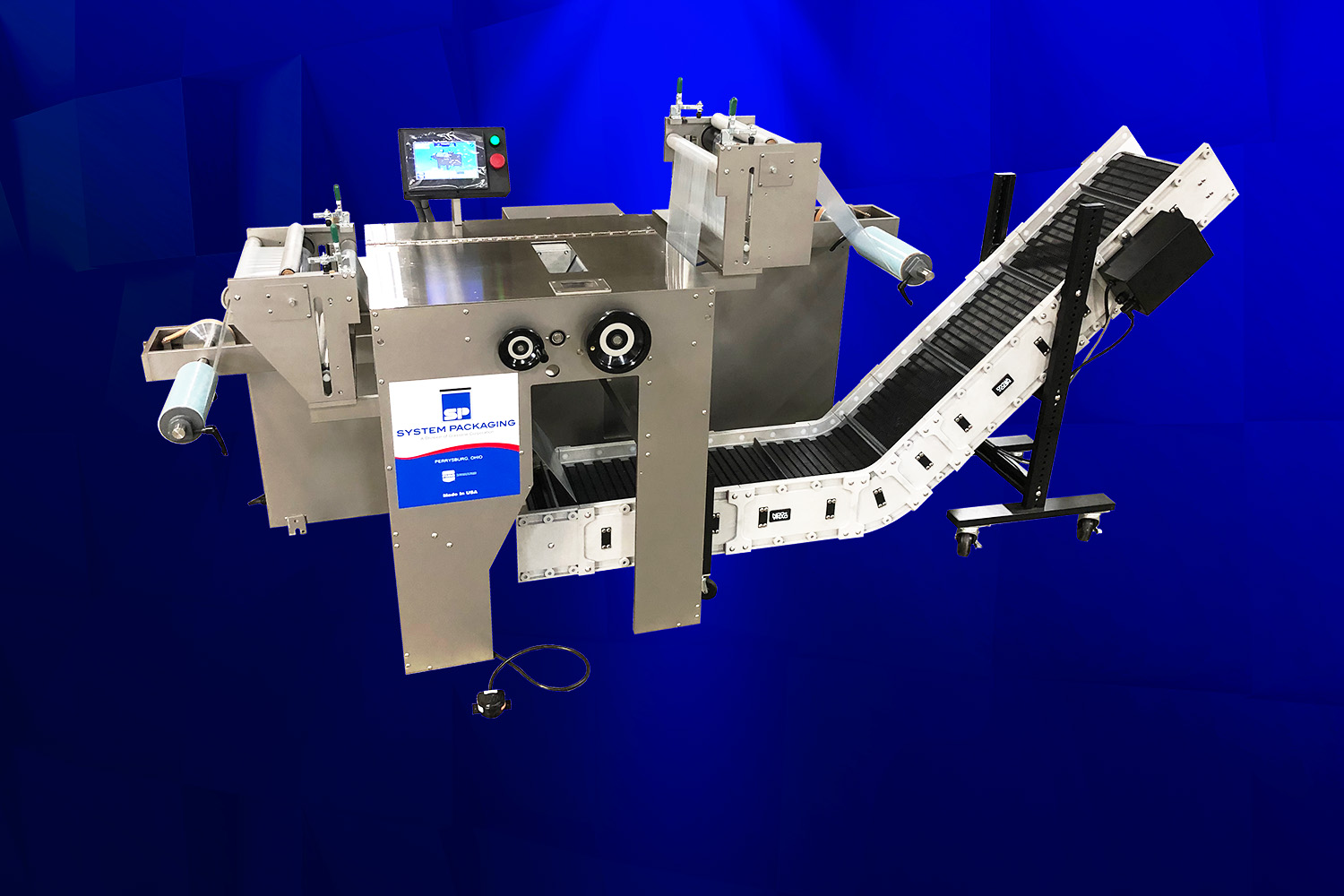

Model 9000

Model 9000 Random Length Double Web Machine Description The 9000 random length machine is equipped with indexing feed fingers to speed the handling and loading of rectangular items such as books, CD’s, etc. It accepts a continuous stream of products varying in length and adjusts the package length accordingly. Speed will vary by length of…