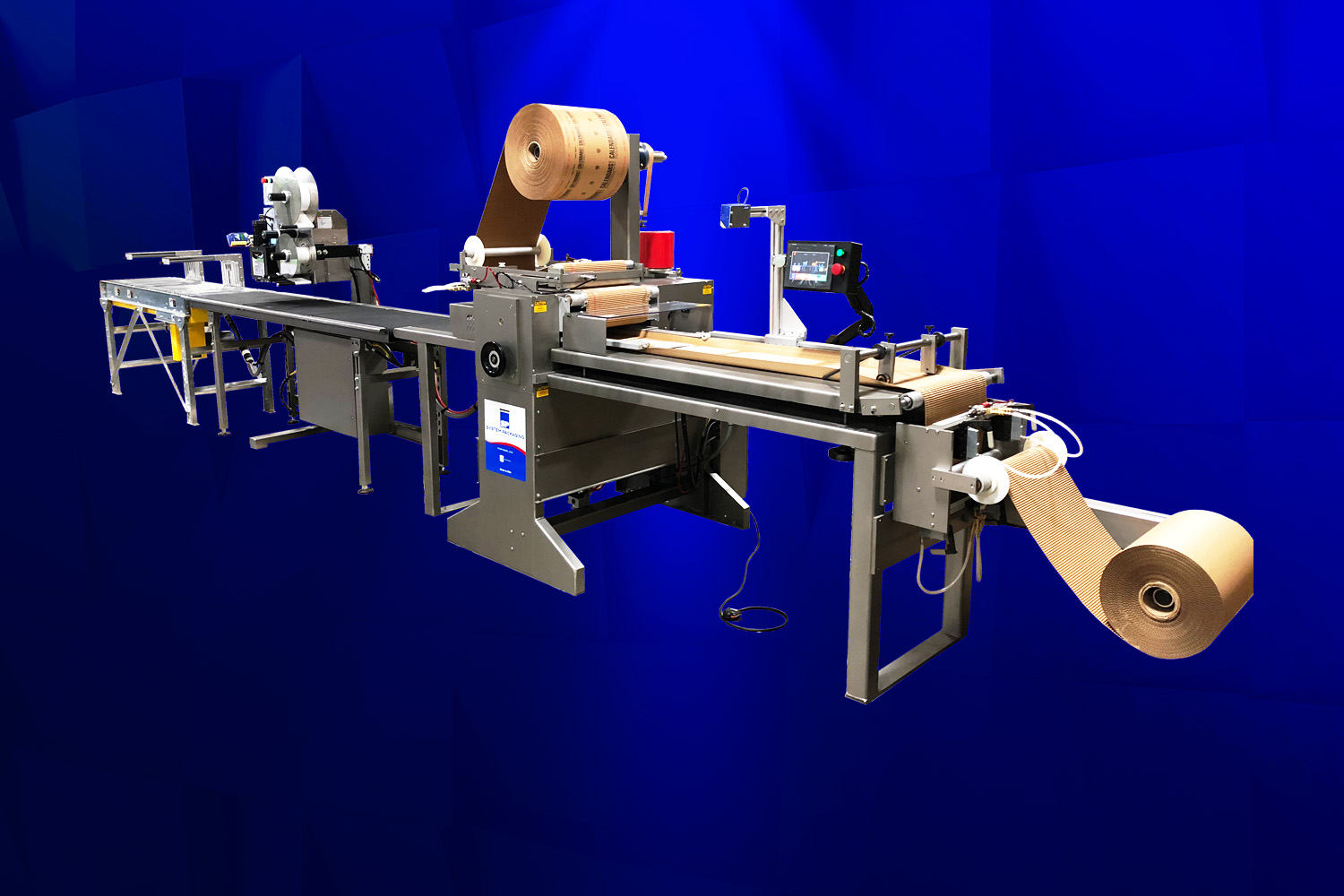

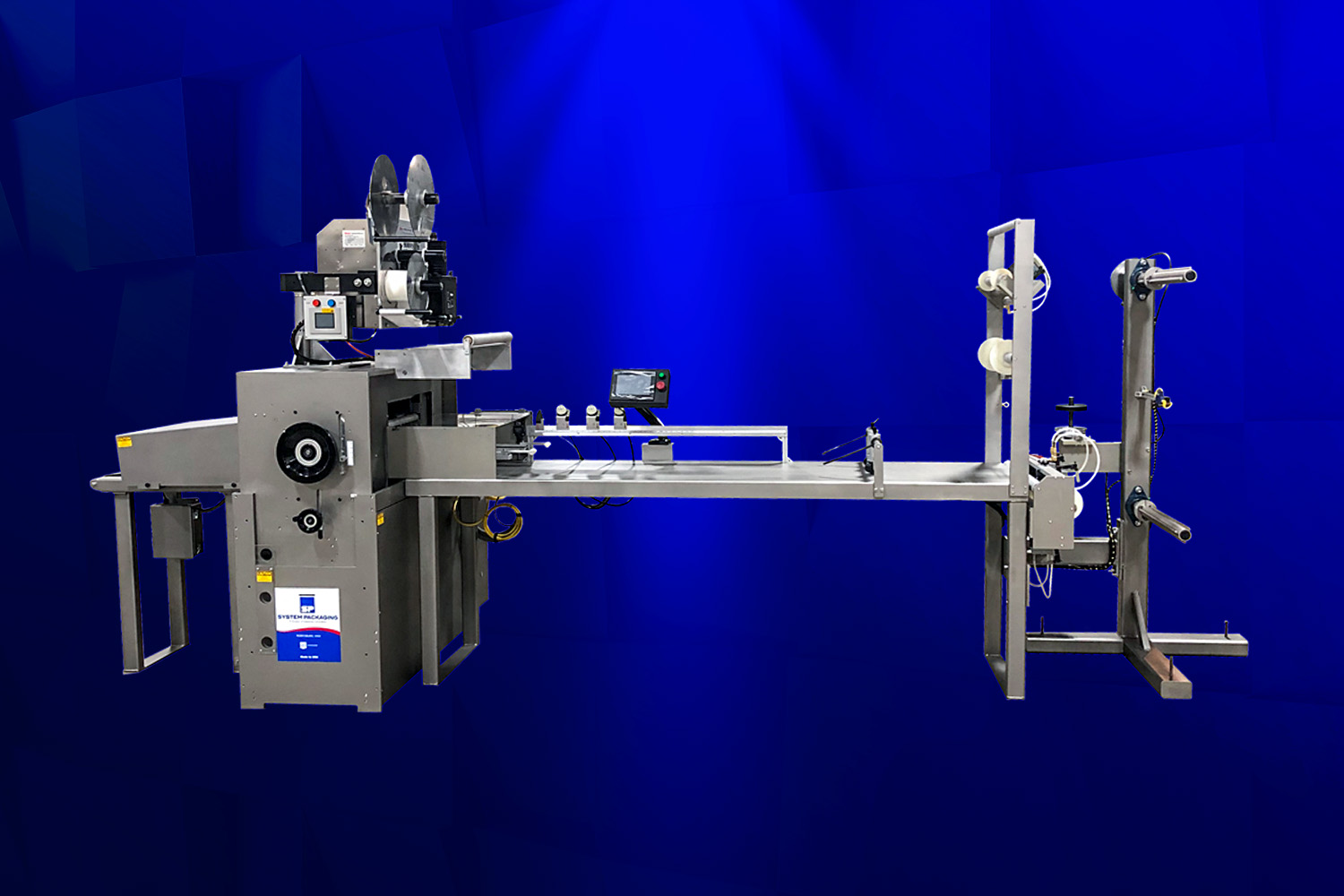

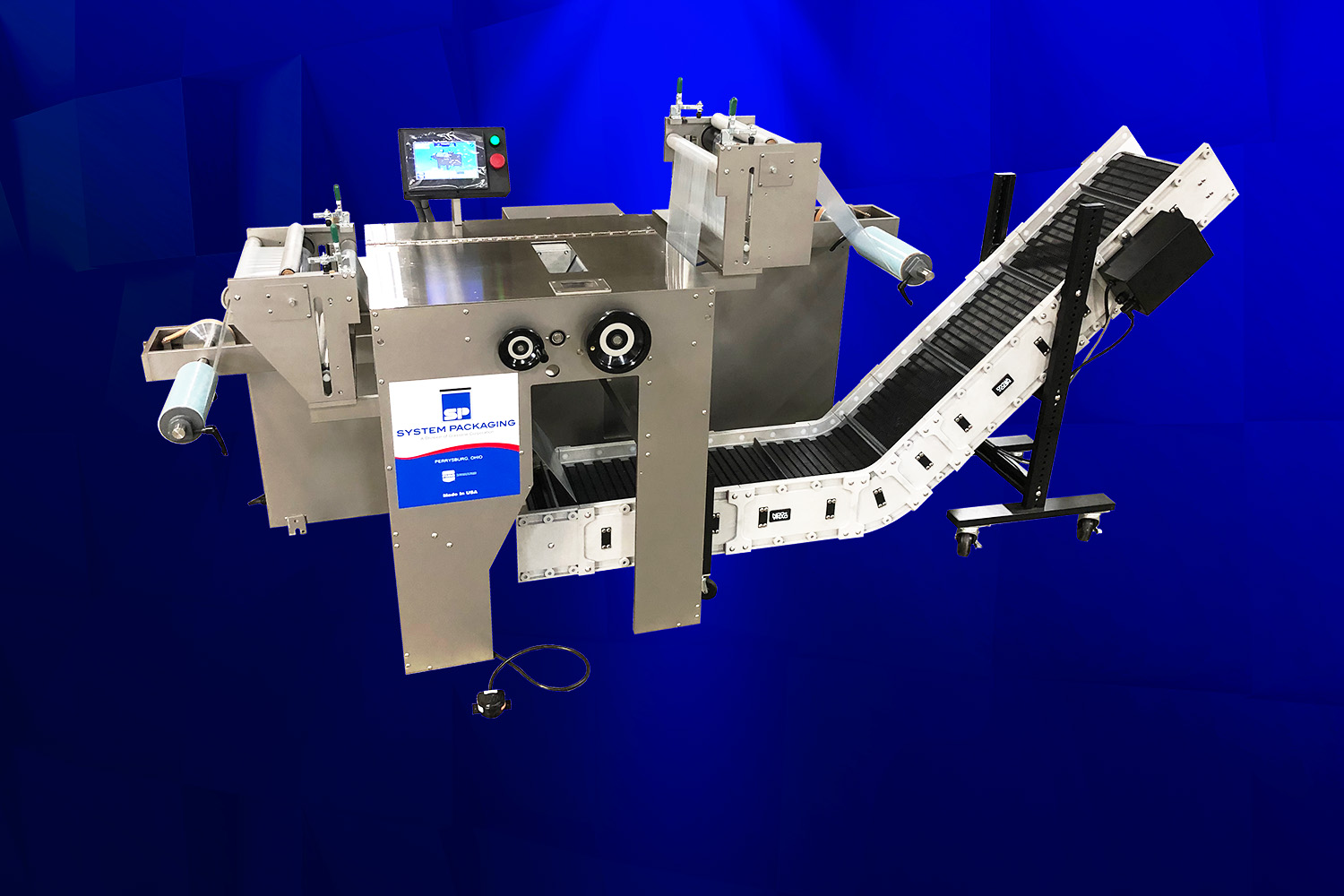

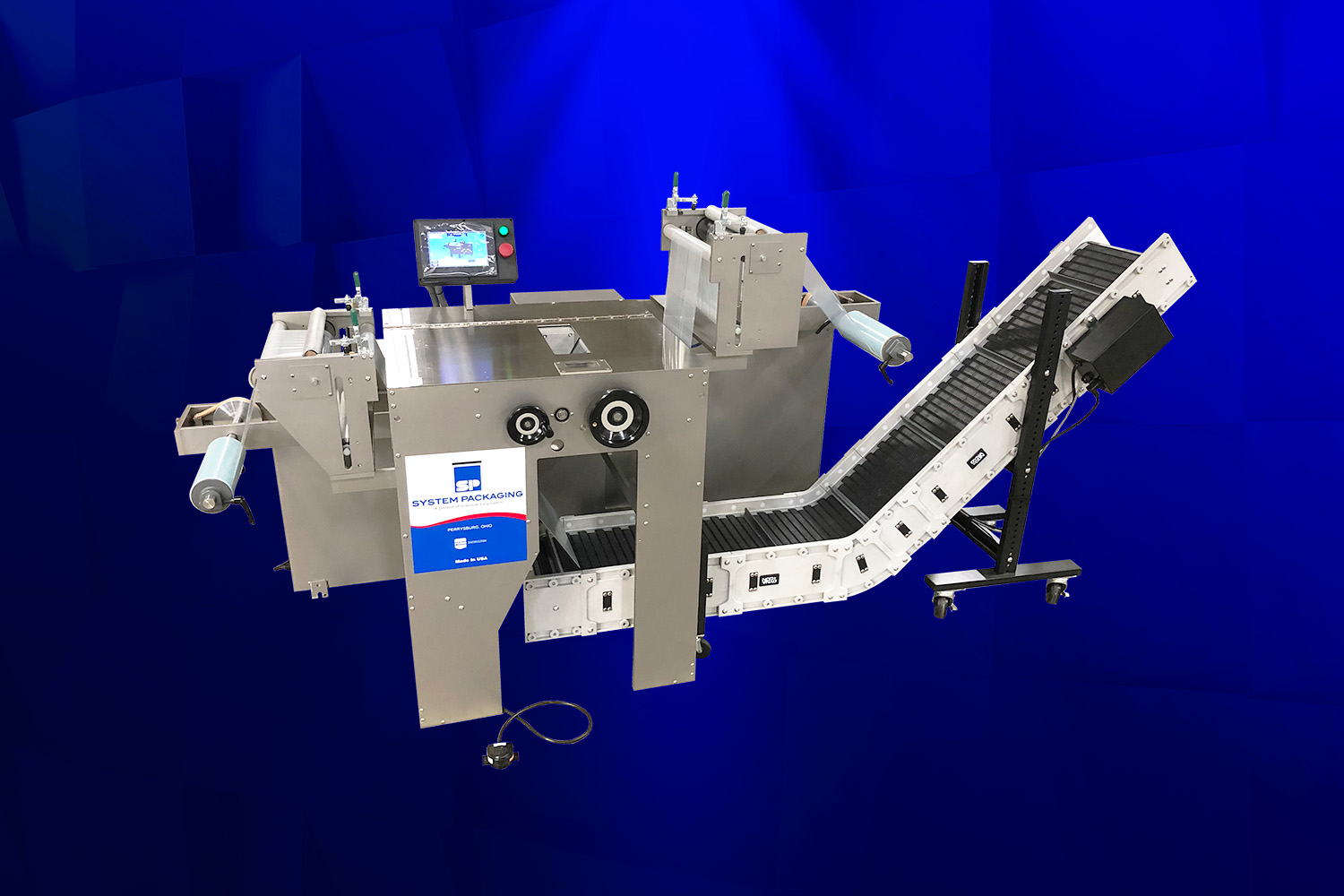

Model 4500 Vertical Pouch Machine

Machine Specifications:

- This machine uses two rolls of cold sea material to make the protective pouch

- Both webs of material come together and create a v-shaped space in which to place products

- Custom funnels and guides can be supplied for the various product ranges

- The side seals and length cutoff are done simultaneously in the sealing head of the system

- The machine uses pre-set length adjustment to regulate the package size

- Machine operation and setup are done through the touch screen controller which allows the operator to make adjustments quickly and easily

- The system is available in 6, 12, and 15″ wide models

- The maximum width and height through the machine varies upon model

- The 4500-6 has a 2″ deep package capability

- The 4500-12 and 4500-15 have a 3.5″ deep package capability

- It uses 110 V.A.C. and 80 P.S.I.

- The units can run up to 35-40 packages per minute

Machine options include, but are not limited to the following:

- Extended roll holders for larger diameter rolls of material

- Custom funnels and accumulators

- Exit conveyors that remove finished packages

- Verifying scanners and rejection stations

- Barcode scanners

- Print and apply label applicators

- Roll printers or coders

Features:

- 6 or 12 inch web width

- Forms pouches as deep as 20”

- No warm-up or cool-off time

- Dial-in length control system lets operator vary pouch length in 1/10”increments for utmost economy of material

- Low electricity consumption…no special ventilation problems

Material Substrates That Can Be Run On

- All of the material has to be cohesive coating.

Have any questions? Feel free to reach out to one of our experts.