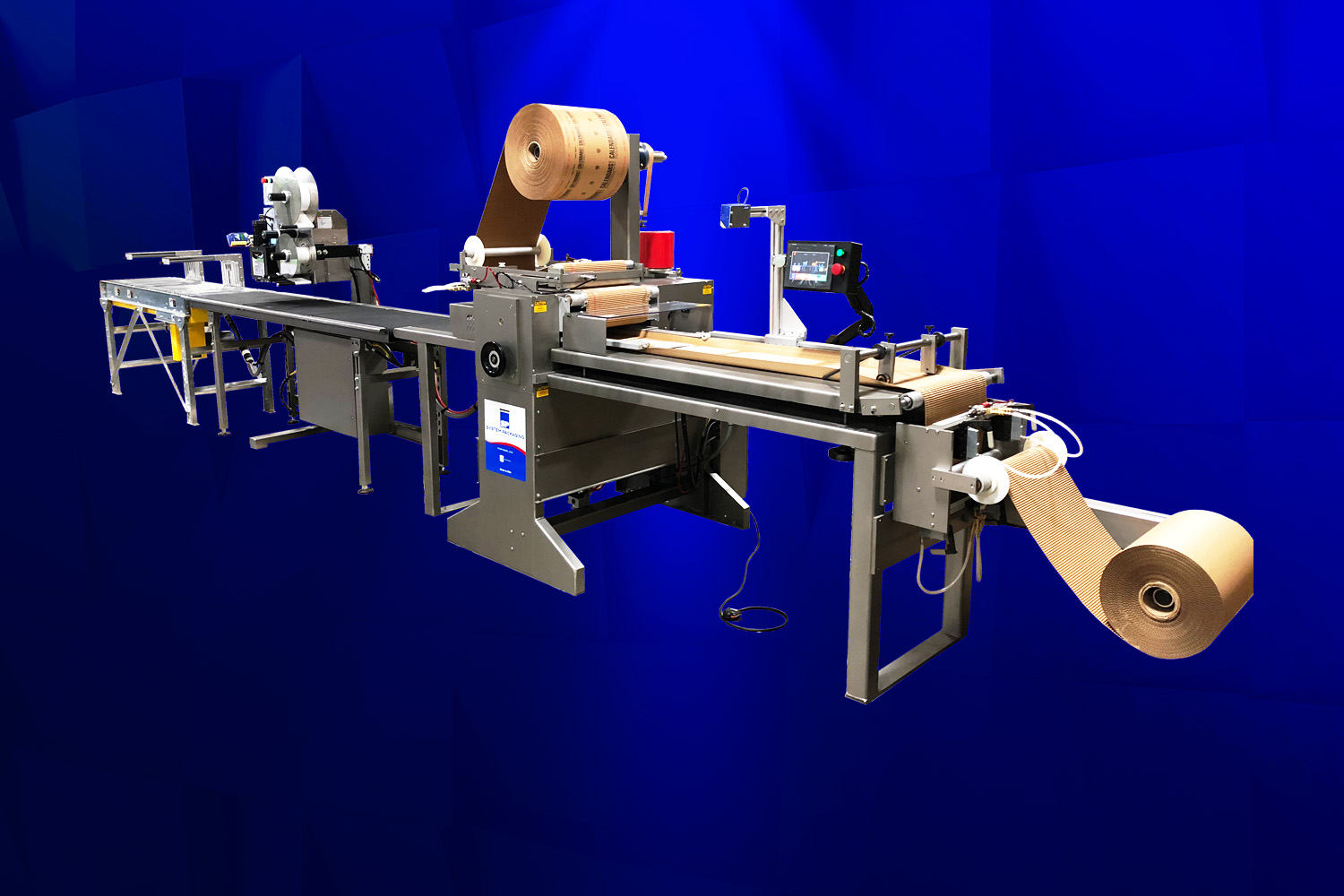

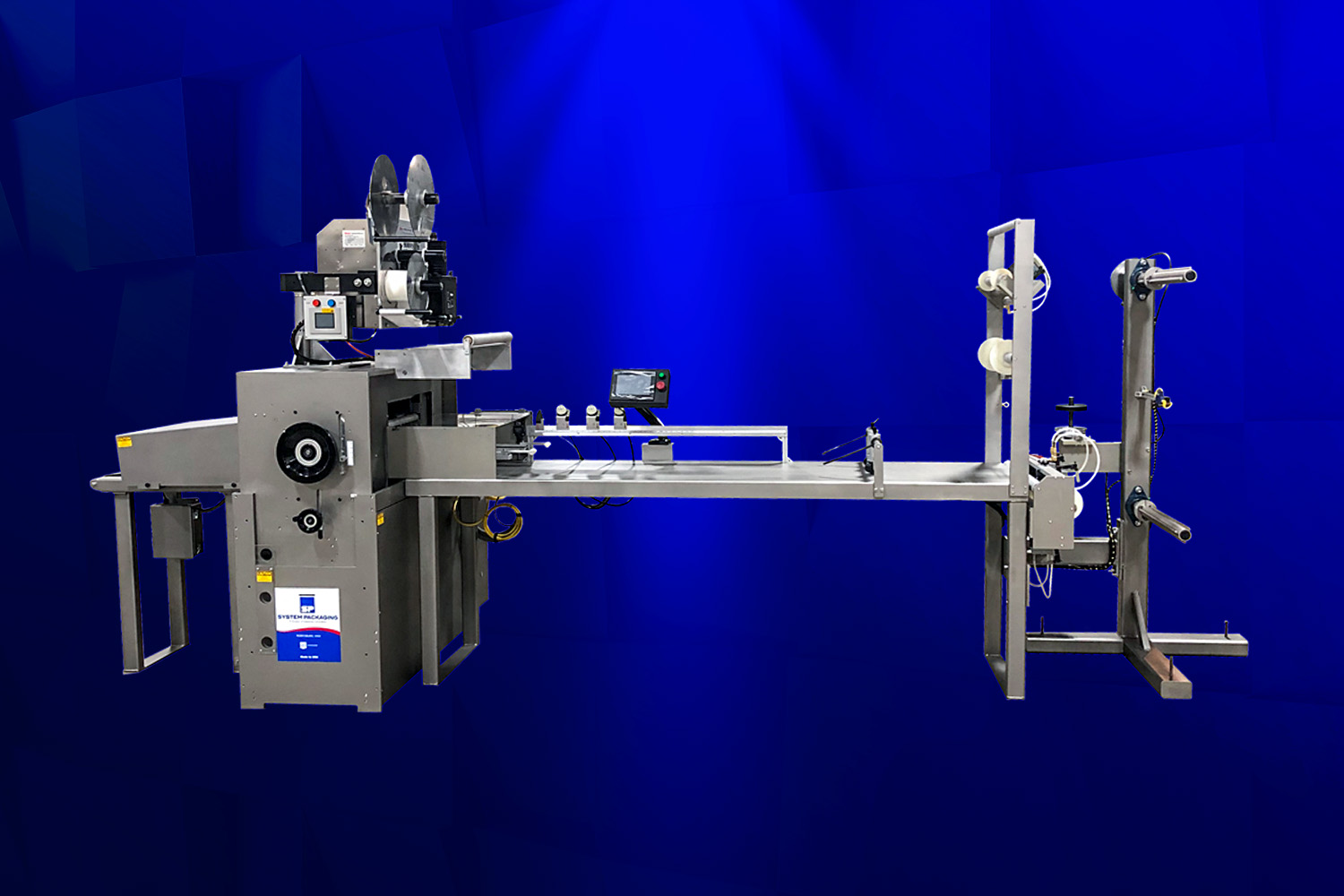

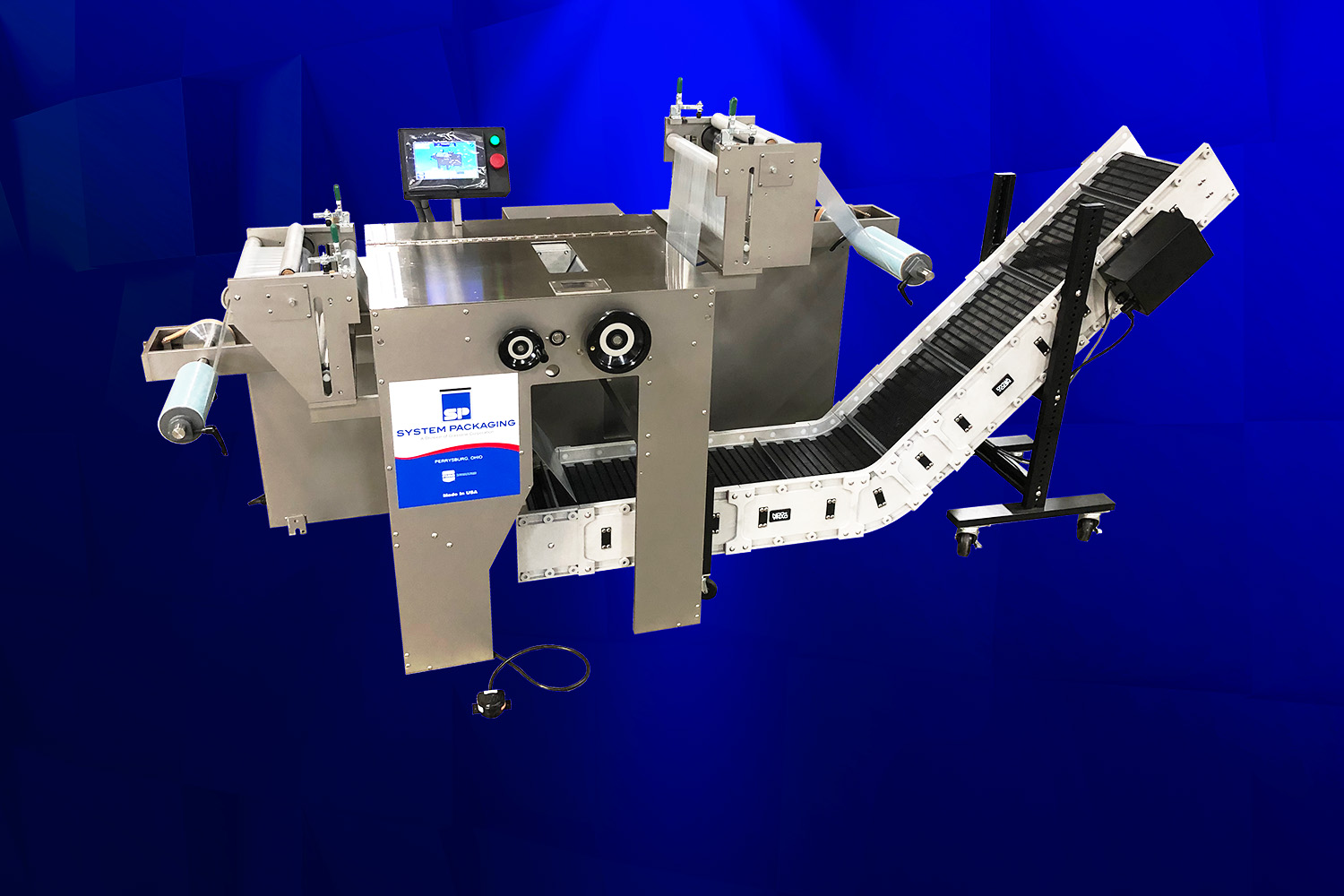

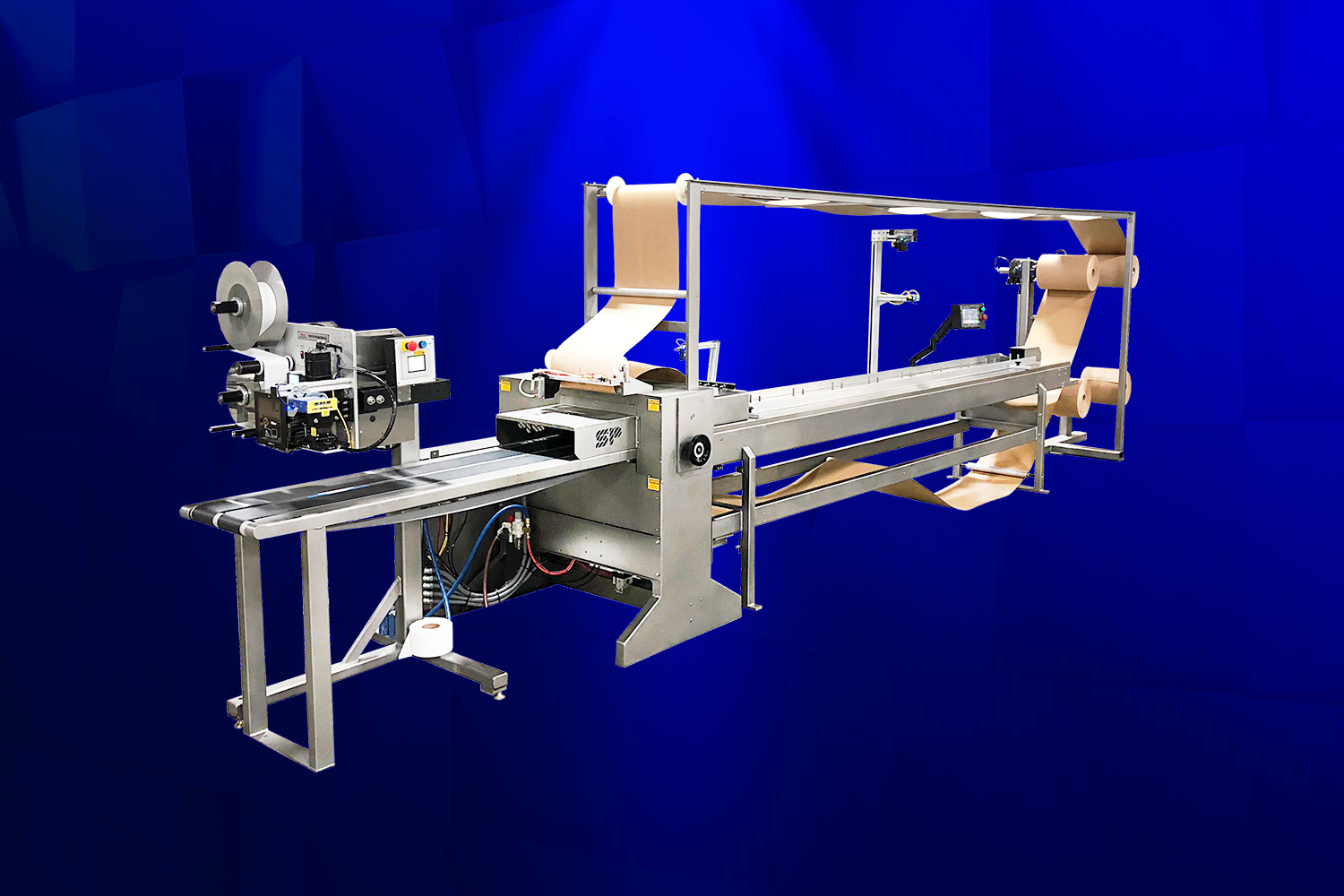

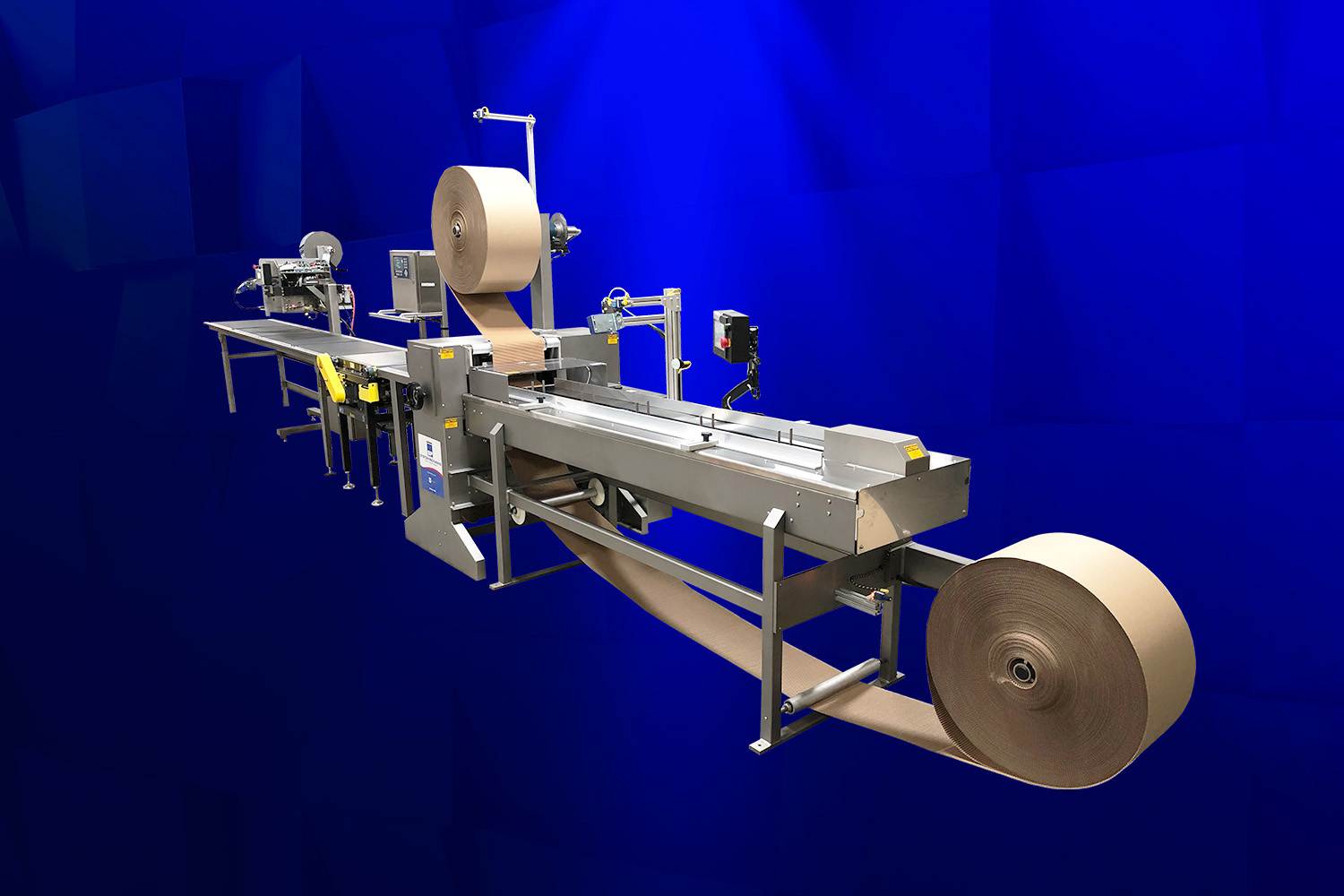

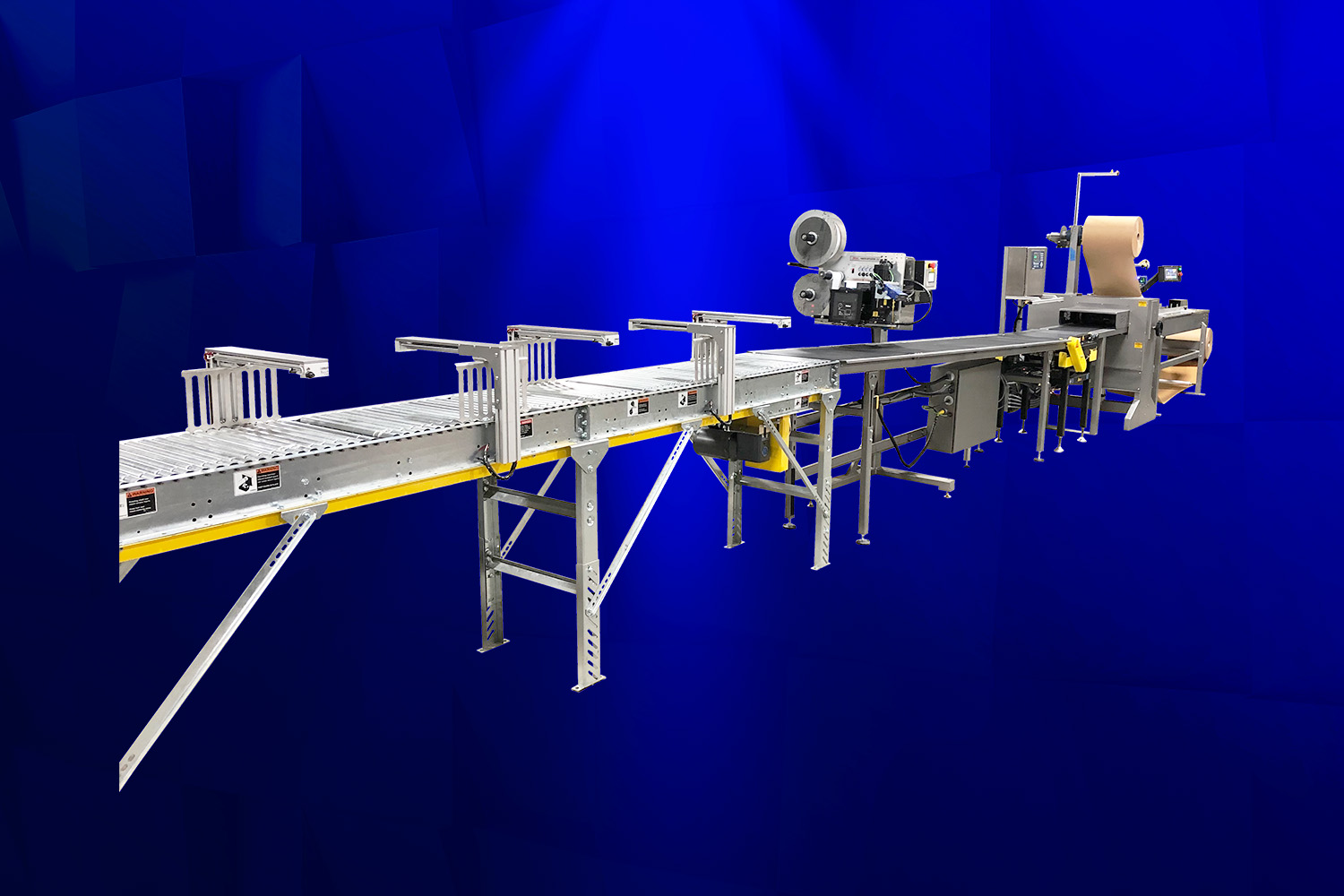

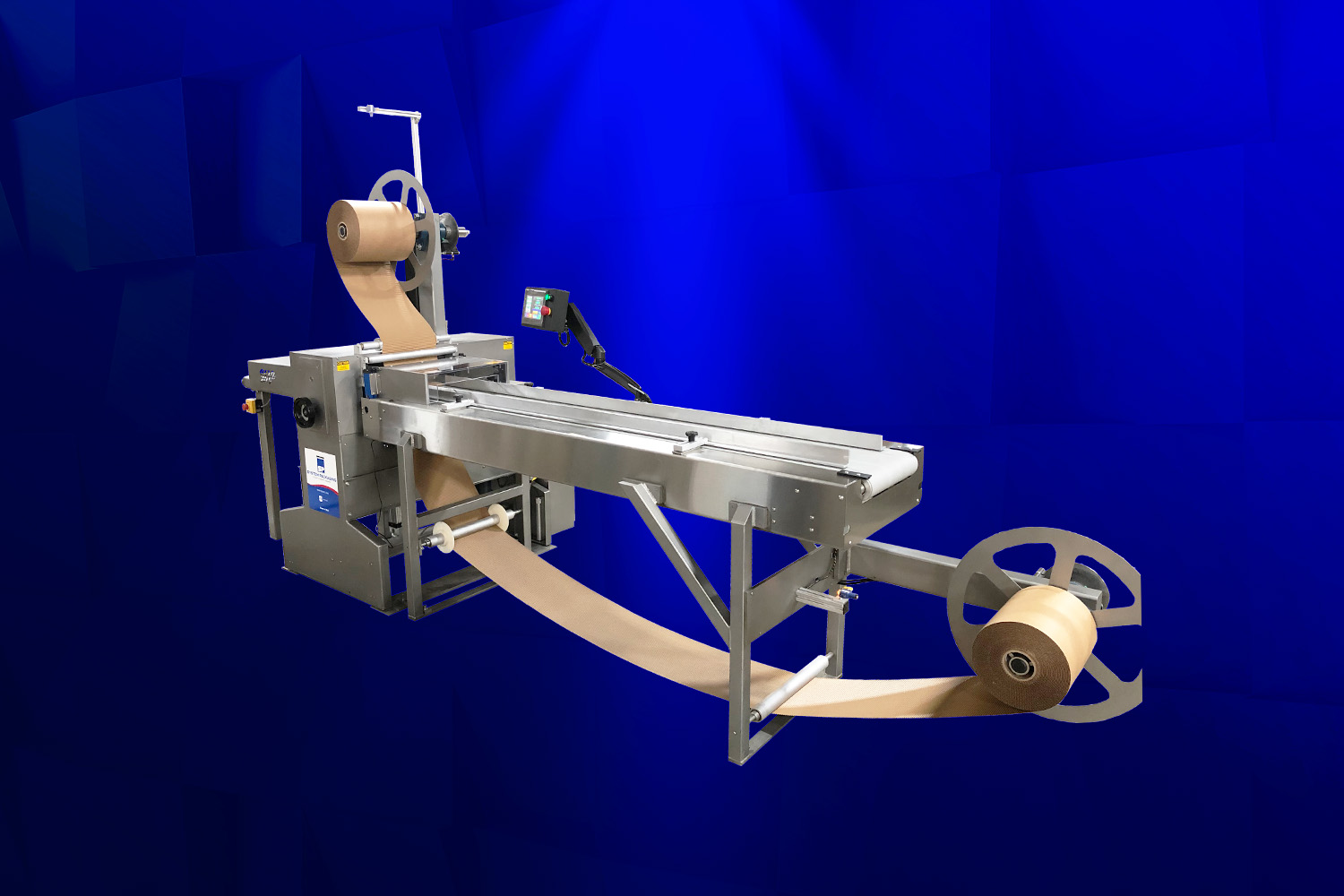

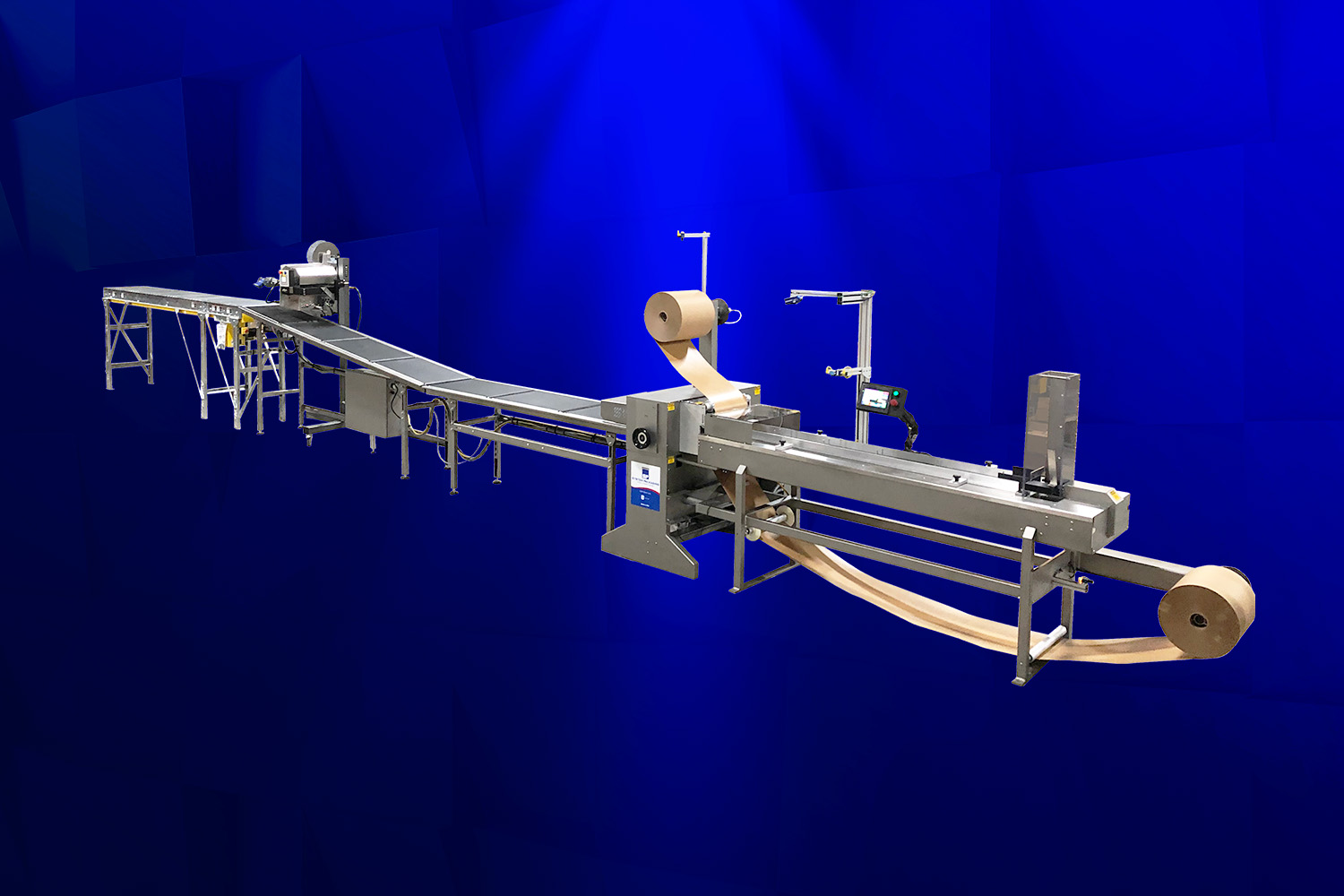

Model 9000 Random Length Double Web Machine

Machine Specifications:

- Tailored for packaging random length and height products or can be used to automate long runs of similar product lines.

- Products range from clothing, books, catalogs, CD’s, to Window Blinds, Moldings door panels, and Trim.

- The 9000 measures the length of the product and makes a package accordingly.

- This machine uses two Rolls of Cold Seal Material to make the protective pouch.

- The infeed conveyor carries the product to the sealing head where both rolls of material come together to form the protective pouch.

- The end seals and length cutoff are done simultaneously in the sealing head of the system.

- Machine operation and setup are done thru the touchscreen controller.

- This allows the operator to make adjustments quickly and easily.

- The system is available in 18″, 24″, and 36″ Wide Models

- The maximum Width and Height thru the machine varies upon Model

- The standard 9000-18 and 9000-24 have a 5″ High Package Capability

- Also available is a 9000-24-8 with an 8″ High Package Capability

- The 9000-36 has an 8″ High Package Capability

- Product lengths on a Flited infeed are limited to the flite spacing (17” O.C. typical).

- Products lengths are unlimited for the belted infeed models.

Machine options include, but are not limited to the following:

- Power Unwind units for certain cohesive materials

- Extended Infeed Conveyors and Exit Conveyors

- Fold over opening device

- Perforators for easy open packages

- Barcode Scanners

- Print and Apply Label Applicators

- Roll Printers or Coders

- Product height/package length sensor

- Product / Package Assist Belted Infeed

- Friction feeders

- Hoppers

- Product ID Tracking Software

- Larger touch screen

- Reject/accumulate system (2sides)

- Nordson melt pick and place

- Singles Mode for High-Speed packaging at set length products and packages

- Inline weight scale

- Printer and inserter

- Package sortation

Features:

- The Standard System has an 8′ Infeed Conveyor and a 3′ Exit Conveyor

- It uses 110 V.A.C. and 80 PSI

- It has a Single roll stand mounted prior to the Infeed Conveyor and one above the sealing head.

- It also has a touchscreen controller with a built-in Batch Counter

- The units can run packages up to 40 packages per minute.

- Pneumatic Spindle Roll Stands for Quick Material Changeover

Material Substrates That Can Be Run On

- All of the material has to be cohesive coated

Have any questions? Feel free to reach out to one of our experts.