Table of Contents

Proper packaging machine maintenance is essential to keep your production line running smoothly, prevent unexpected downtime, and avoid costly repairs. By implementing a structured maintenance program, you can extend the lifespan of your equipment and ensure consistent performance. Neglecting routine maintenance can lead to breakdowns, reduced efficiency, and higher operating costs.

Understanding Industrial Packaging Machine Maintenance

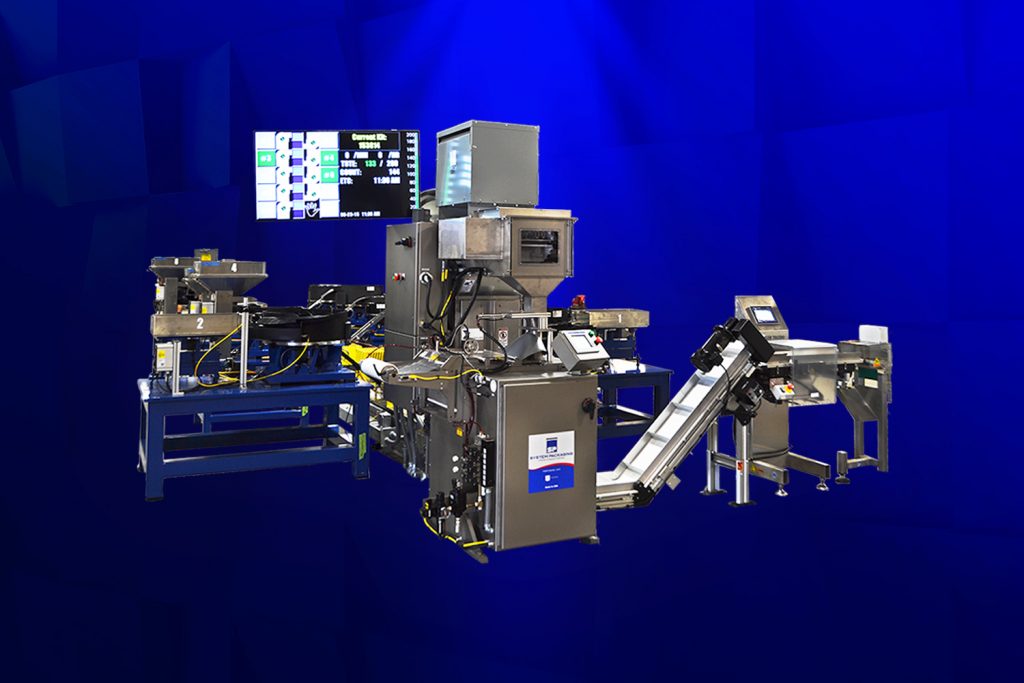

Packaging machines are an essential investment in any production facility, and keeping them in optimal condition is key to maintaining efficiency. System Packaging offers a range of industrial packaging machinery designed for durability and performance, making proper maintenance even more critical.

Maintenance for industrial packaging machines involves regular inspections, cleaning, lubrication, and timely repairs. A proactive approach helps identify potential issues before they escalate, ensuring minimal disruption to operations. Consistently maintaining your equipment also enhances safety, improves product quality, and extends the lifespan of critical components.

Developing a Packaging Machine Maintenance Checklist

Creating a structured packaging machine maintenance checklist ensures that all necessary tasks are completed at the right intervals. Following a checklist minimizes oversight and enhances overall efficiency.

Daily Checks:

- Visual Inspection: Look for signs of wear, loose components, or misalignments that may impact performance.

- Cleaning: Remove dust, debris, and residue to prevent contamination and ensure sensors and moving parts are unobstructed.

- Lubrication: Apply manufacturer-recommended lubricants to moving parts to prevent friction and wear.

Weekly Tasks:

- Component Testing: Check belts, chains, gears, and tensioners for wear or misalignment.

- Safety Features: Ensure emergency stop buttons, sensors, and safety guards function correctly.

Monthly Maintenance:

- Electrical Systems: Inspect wiring, connections, and power supplies for signs of damage or corrosion.

- Calibration: Verify that sensors, weighing systems, and automated settings are correctly adjusted for accuracy.

Quarterly Reviews:

- Deep Cleaning: Conduct thorough cleaning of all internal and external parts, focusing on buildup-prone areas.

- Software Updates: Install firmware or software updates to optimize performance and security.

Annual Overhaul:

- Professional Inspection: Engage certified technicians to conduct a detailed assessment and performance test.

- Parts Replacement: Identify and replace worn-out or obsolete components to prevent failures.

Preventative Measures to Avoid Downtime

Reducing unexpected downtime requires proactive measures beyond scheduled maintenance. Taking a few extra steps can improve efficiency and prevent costly disruptions.

- Training Operators: Ensure machine operators receive proper training on usage, troubleshooting, and safety procedures.

- Spare Parts Inventory: Keep essential spare parts on hand to reduce downtime when replacements are needed.

- Documentation: Maintain a record of maintenance activities, repairs, and part replacements to track machine health over time.

- Scheduled Shutdowns: Plan maintenance during non-peak hours to minimize impact on production schedules.

Packaging Machine Troubleshooting Tips

Even with regular maintenance, occasional issues may arise. Knowing how to troubleshoot common problems can help prevent minor issues from escalating into major breakdowns.

- Inconsistent Seals: Check temperature settings, sealing bars, and film alignment. Worn-out sealing components should be replaced.

- Jamming: Ensure proper material loading, remove debris, and check for misaligned components.

- Sensor Errors: Clean and realign sensors to ensure accurate detection of materials and products.

- Irregular Product Dispensing: Inspect weighing and measuring components to ensure accurate product flow.

- Machine Not Powering On: Check power sources, fuses, and wiring connections for faults.

When to Seek Professional Packaging Equipment Repair Services

While regular maintenance can prevent most issues, some situations require expert intervention. Professional packaging equipment repair services can help diagnose and fix complex problems.

- Persistent Problems: If an issue recurs despite troubleshooting, professional assistance may be necessary.

- Complex Repairs: Electrical or mechanical failures beyond basic maintenance should be handled by experienced technicians.

- Safety Concerns: If a malfunction poses a safety risk, shut down the machine and contact a service professional immediately.

- End-of-Life Components: Some machine parts wear out over time and may require professional servicing or replacement.

FAQs About Packaging Machine Maintenance

Proper maintenance helps prevent costly repairs, but questions still arise regarding best practices and troubleshooting. Below are some frequently asked questions to help you maintain your industrial packaging machine effectively.

How often should I perform maintenance on my packaging machine?

Daily inspections are recommended, with deeper maintenance performed weekly, monthly, quarterly, and annually.

What are the benefits of a maintenance checklist?

A checklist ensures all necessary tasks are completed systematically, reducing the risk of overlooking critical maintenance activities.

Can regular maintenance reduce the need for packaging machine repair?

Yes, proactive maintenance helps identify and address potential issues before they lead to costly breakdowns.

What should I do if my machine frequently jams?

Regular cleaning, proper loading procedures, and realigning components can prevent frequent jamming issues.

Why is professional servicing important?

Certified technicians have specialized knowledge and tools to handle complex repairs, ensuring long-term machine reliability.

Keep Your Packaging Machines Running at Peak Performance

Keeping your packaging machinery in optimal condition requires regular maintenance and professional support. At System Packaging, we offer comprehensive services and parts to keep your equipment running smoothly. Visit our Services and Parts page to learn more about how we can help you maintain peak production efficiency.