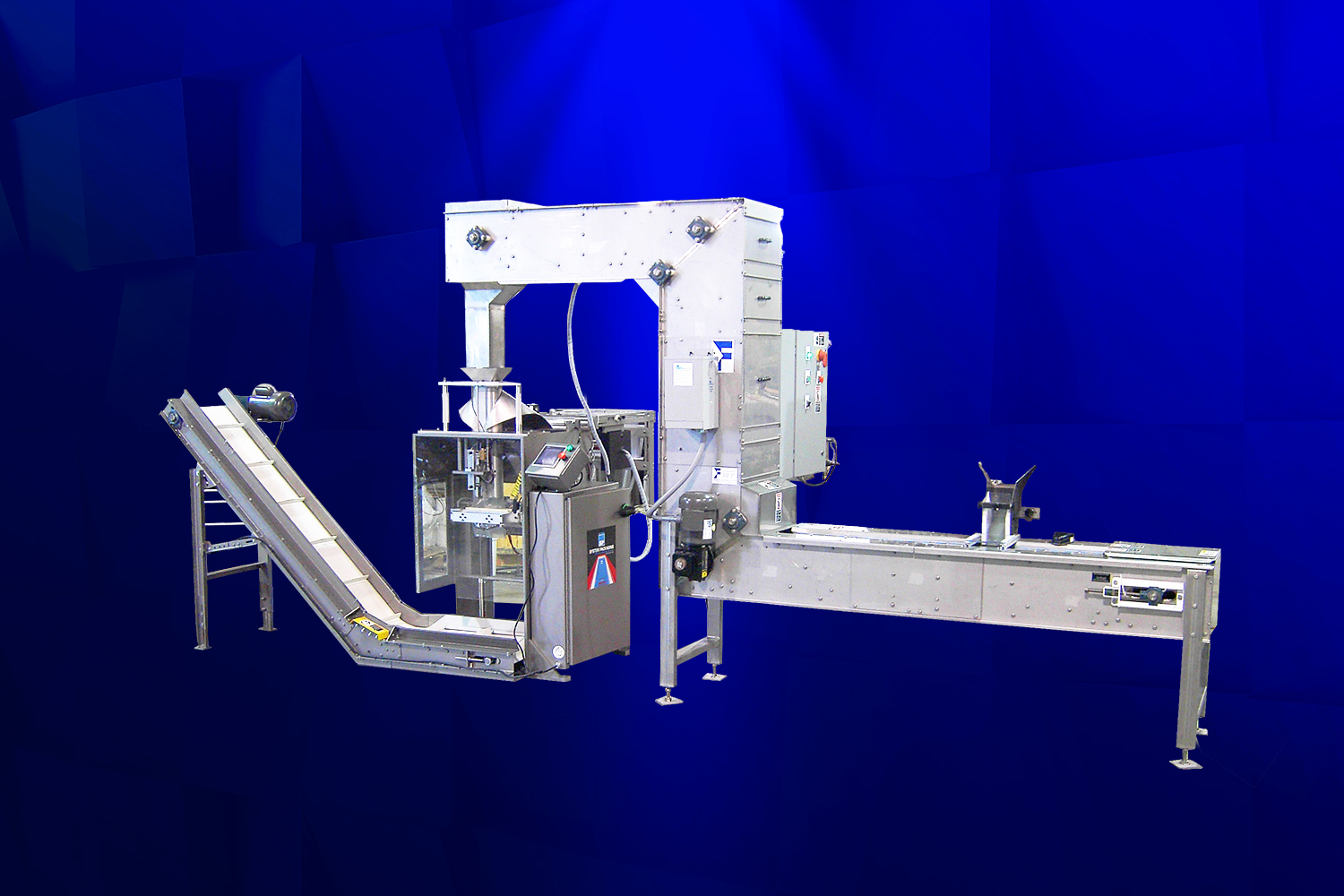

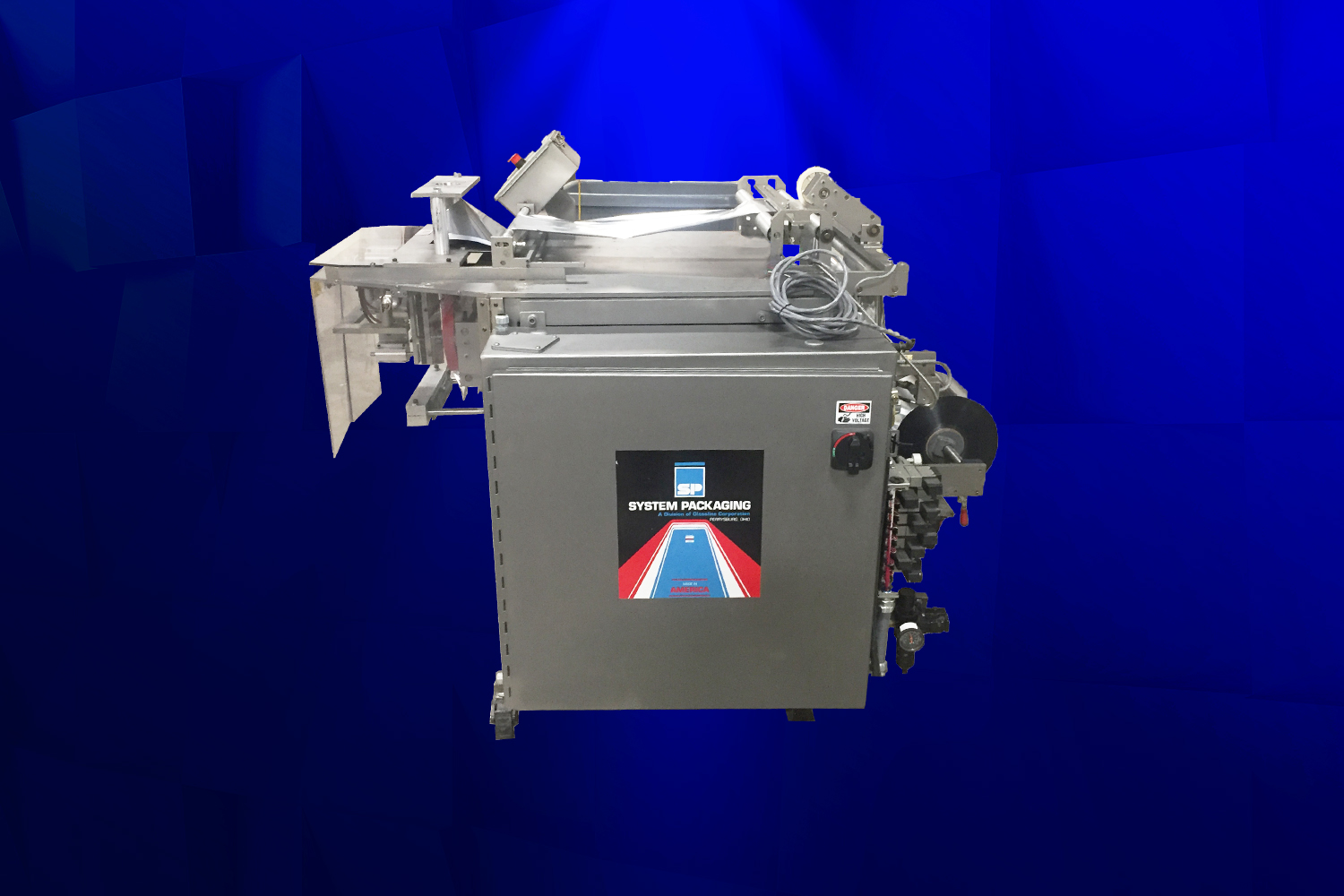

Model 1200

Model 1200 Vertical Form, Fill and Seal Machine The Model 1200 machines are highly reliable, microprocessor-controlled, and can cut your packaging costs by up to 70%. Using inexpensive polyethylene or other colaminate roll stock, these systems produce 25-30 bags per minute, depending on the model, package size, and product. The 1200 will free you from…