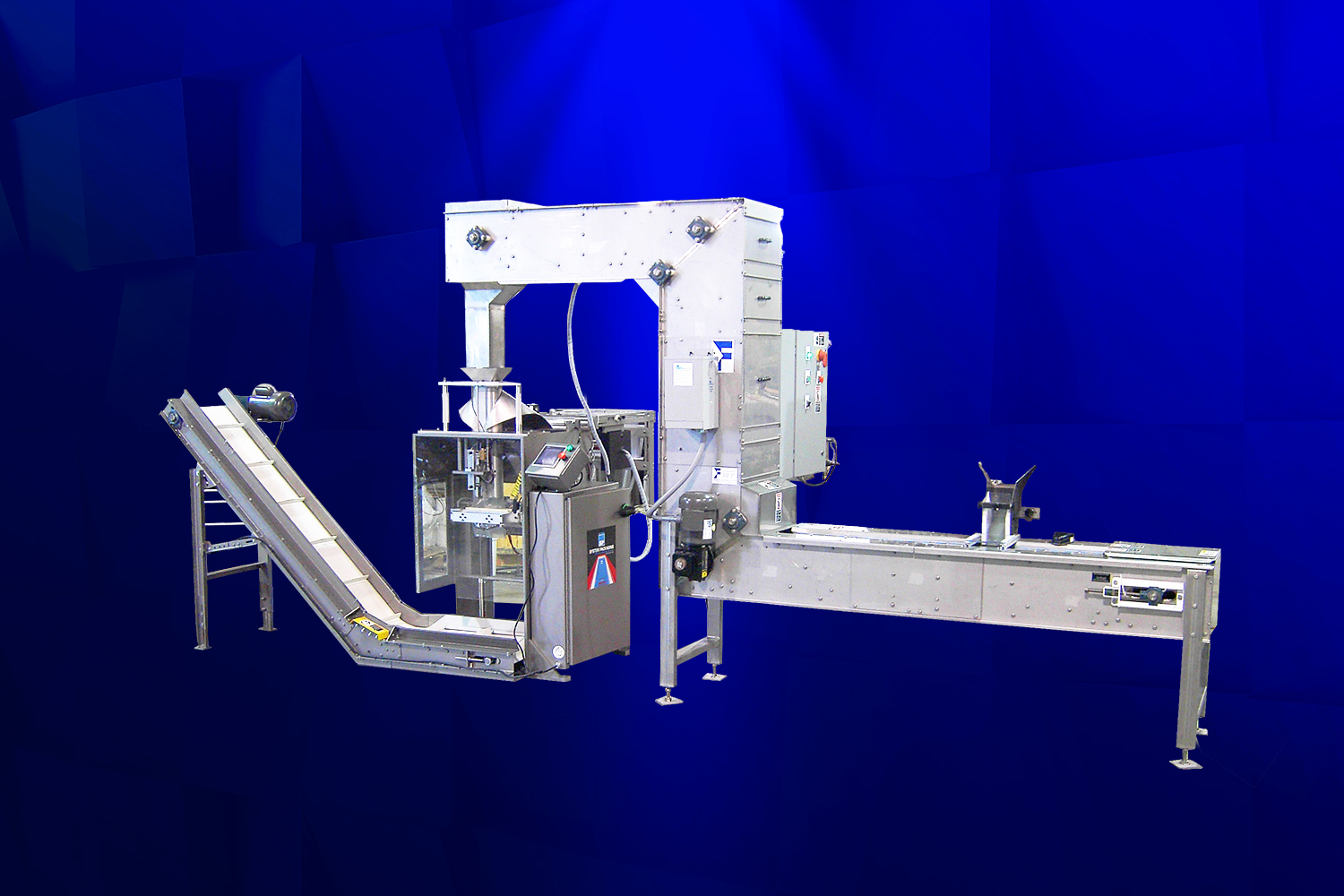

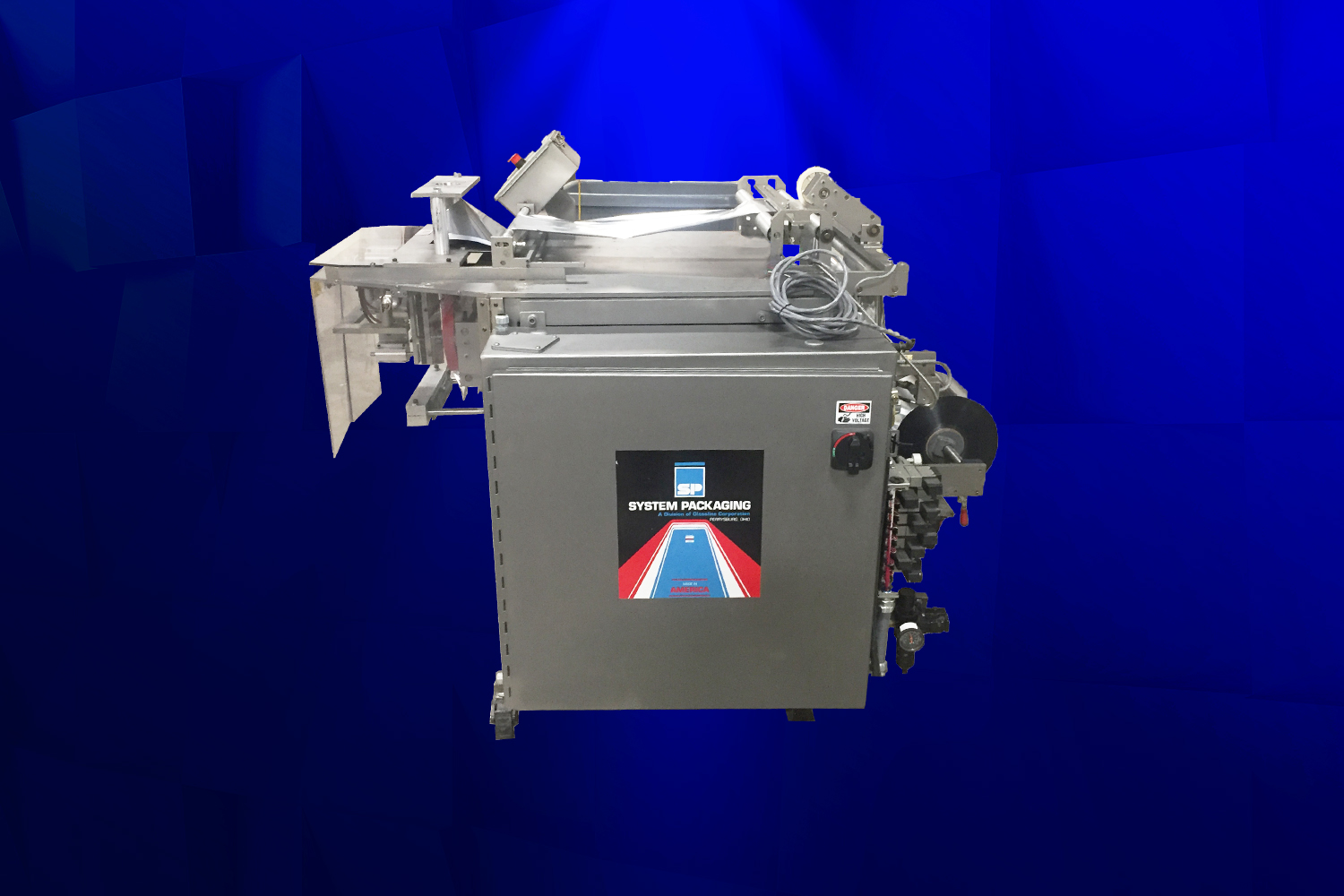

Mark 12 Vertical Form, Fill and Seal Machine

Machine Specifications:

- Capable of producing up to 40 to 50 packages per minute.

- The Mark 12 has a belt-driven material advance for bag length.

- The sealing head does the end seals and length cutoff simultaneously.

- This machine uses one roll of heat seal-able flat stock material.

- The bag width is fixed based on the particular forming collar and material web width.

- The material has a power unwind that controls material tension and an encoder that regulates package length.

- An optional photoelectric eye can be used for print registered material.

- Machine operation and setup are done thru the touch screen controller.

- This allows the operator to make adjustments quickly and easily.

- The system is available in 6″, 8″ and 12″ Wide Models

- The Mark 12-6 can make a bag from 2″ to 6″ wide and up to 10″ long.

- The Mark 12-8 can make a bag from 2″ to 8″ wide and up to 15″ long.

- The Mark 12-12 can make a bag from 3″ to 12″ wide and up to 16″ long.

- Most all heat seal materials can be run on the model MK 12.

- It uses 230 V.A.C. and 80 PSI

- It also has a built in Batch Counter

Features:

- Microprocessor Controlled

- Self Diagnostic Indicators

- Touch Panel Control

- RS232 Interface Capability For User Written Communication Software Package

- NEMA 12 Enclosure

- Disconnect Switch Flange Mounted Fused Primary

- Choice of 230/460 Volt Operation

- Belt Film Feed

- Quick Removable Horizontal Sealer Swing-Out Vertical Sealer

- Material Power Unwind

- Extremely Compact and Low Profile

- Heavy Duty Steel Frame

- Aluminum Tooling Plate Parts with Blasted Oxide Finish

- Two-Part Epoxy Paint Finish

- Stainless Steel Guards and Panels Easily Removed and Installed Without Tools

Machinery Options:

- Casters

- Pre-set Batch Counter

- Totalizing Counter

- Electric Eye (For Registered Film)

- Hole Punch (Hang Hole)

- Hole Punch (Air Evacuation)

- Hot Stamp Imprinter

- Ink Imprinter

- Matrix Printer

- Bar Coding Printer

- Automatic Batch Scales

- Electronic Counting And Feeding System

- Volume Filling

- Liquid Dispensing

- Incline Exit Conveyor

- Indexing Infeed Bucket Conveyor

- Multiple Compartment Bag

- Header Bag

- Additional Options For Specific Application Are Available

Material Substrates That Can Be Run On

- All of the material has to be cohesive coating.

Have any questions? Feel free to reach out to one of our experts.