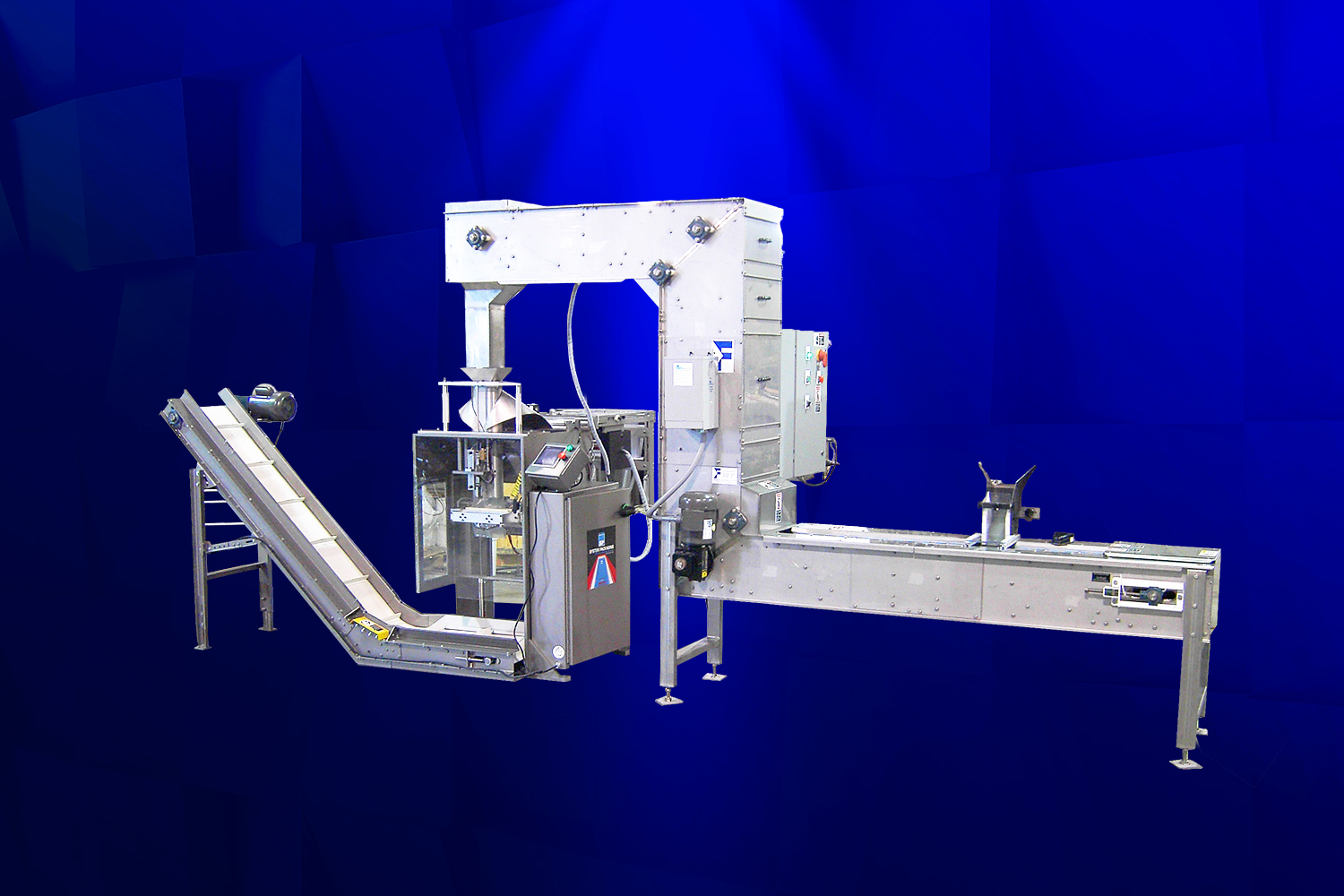

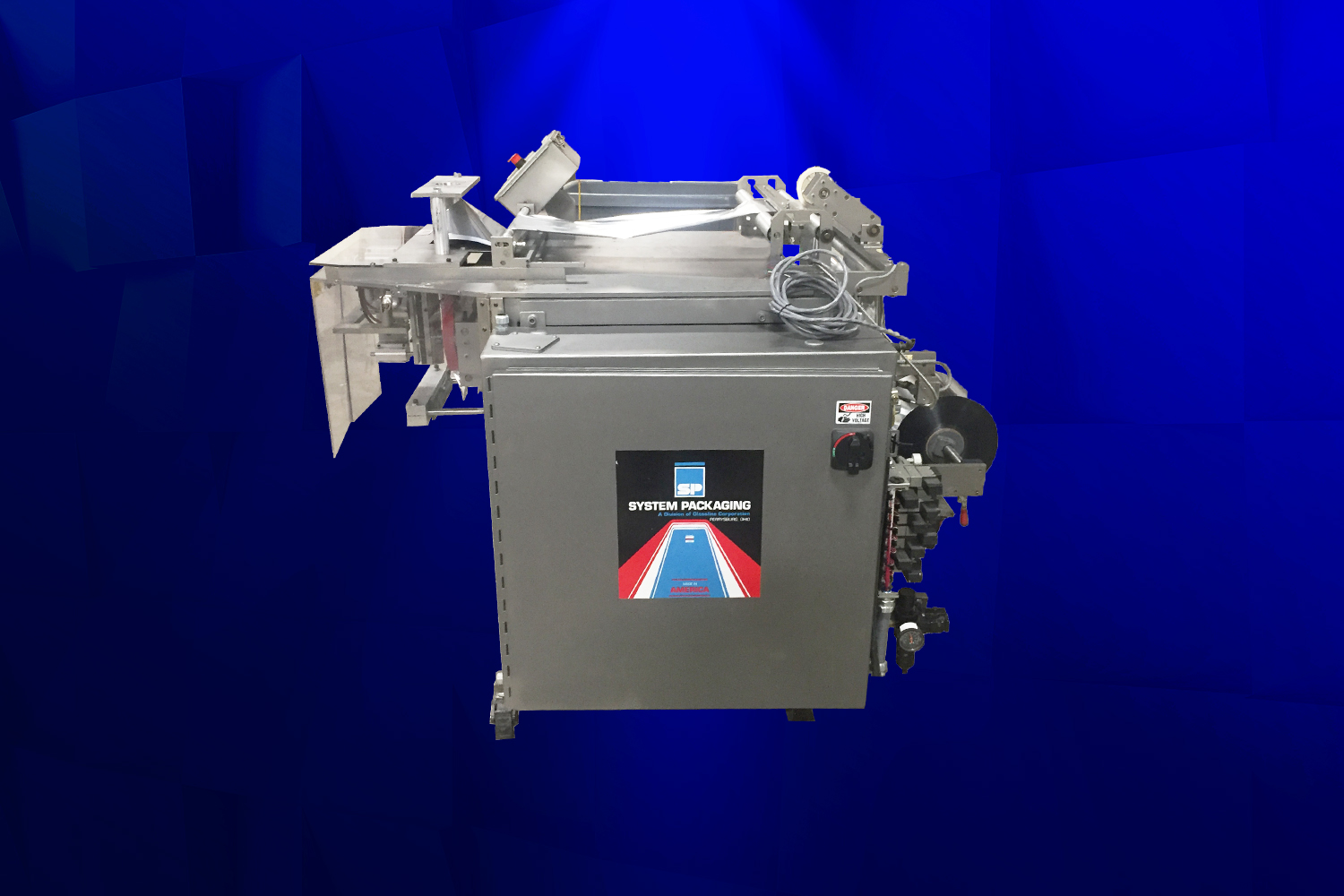

Model 1100 Zipper Style Bagging Machine

Machine Specifications:

- Capable of producing up to 25 packages per minute

- The 1100 has a reciprocating sealing head that advances the material for bag length

- The sealing head does the end seals and length cutoff simultaneously

- This machine uses one roll of heat sealable centerfold zipper material

- The bag width is based on the material web width

- The material has a dancer and brake that controls material tension and an encoder that regulates package length

- An optional photoelectric eye can be used for print registered material

- Machine operation and setup are done thru the touch screen controller which allows the operator to make adjustments quickly and easily

- The 1100-10 can make a bag from 2″ to 10″ wide and up to 12″ long

- Most all heat seal materials can be run on the Model 1100.

- It uses 110 V.A.C. and 80 PSI

- It also has a built-in batch counter

Machine options include, but are not limited to the following:

- Heavy duty locking casters

- Photo electric eye for print registered material

- Thermal transfer printers and coders

- Various weigh, count and escapement systems can be integrated to automatically supply the system with product

- Perforators for easy open packages

- Header seal and hang hole punch

- Exit conveyors to remove finished bags

- Tamper evident seal

Features:

- Standard 2” – 10” package width, 2” – 12” package length

- Delivers up to 25 sealed packages per minute

- Dial-in length control system lets operator vary bag length in 1/10” increments through-out the range of the machine

- Various weigh, count and escapement systems can be integrated to automatically supply the system with product

- Uses inexpensive 2 to 4 mil polyethylene reclosable roll stock, plain or imprinted

- Fully automatic operation with adjustable dwell-time

Can Be Run On

Have any questions? Feel free to reach out to one of our experts.