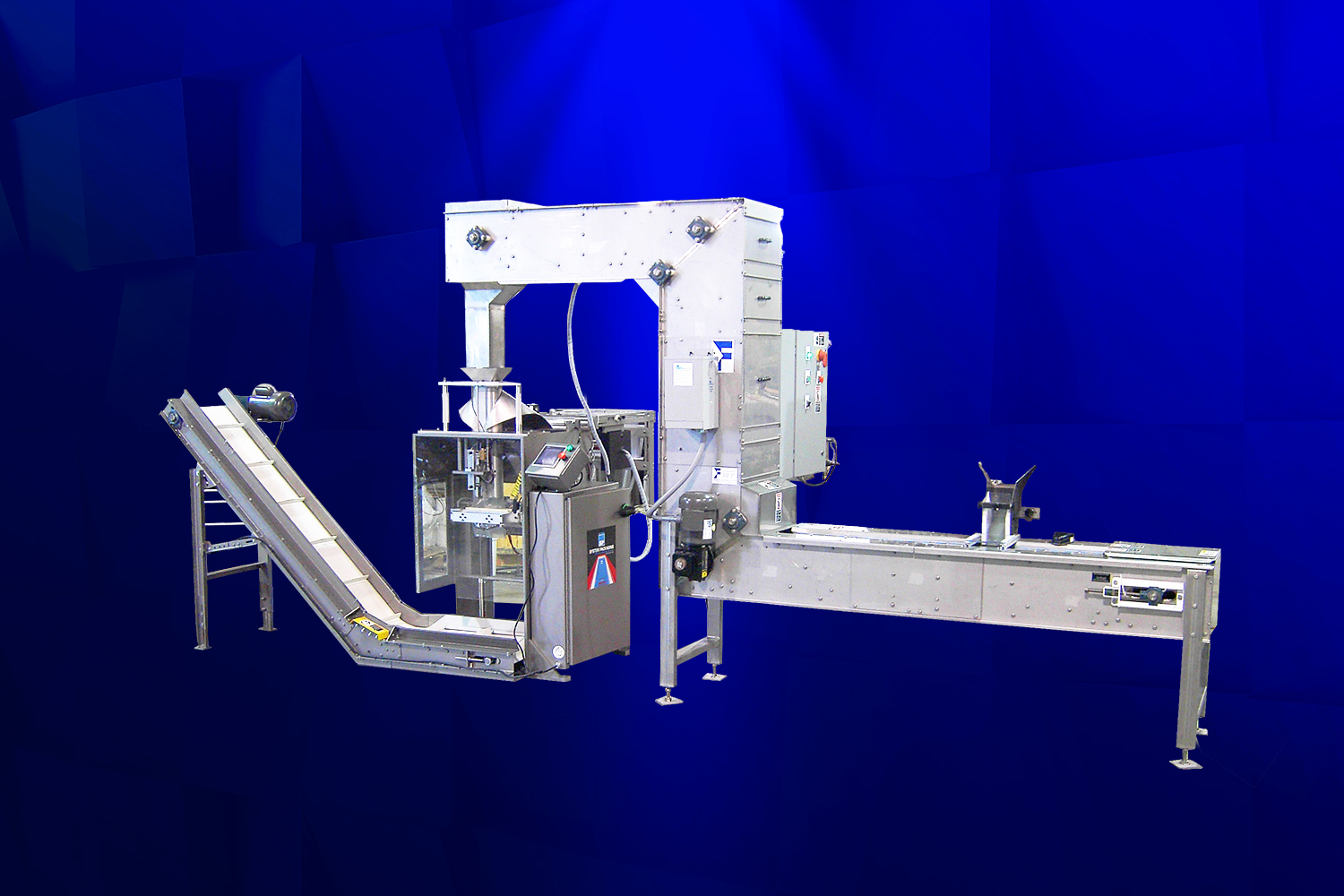

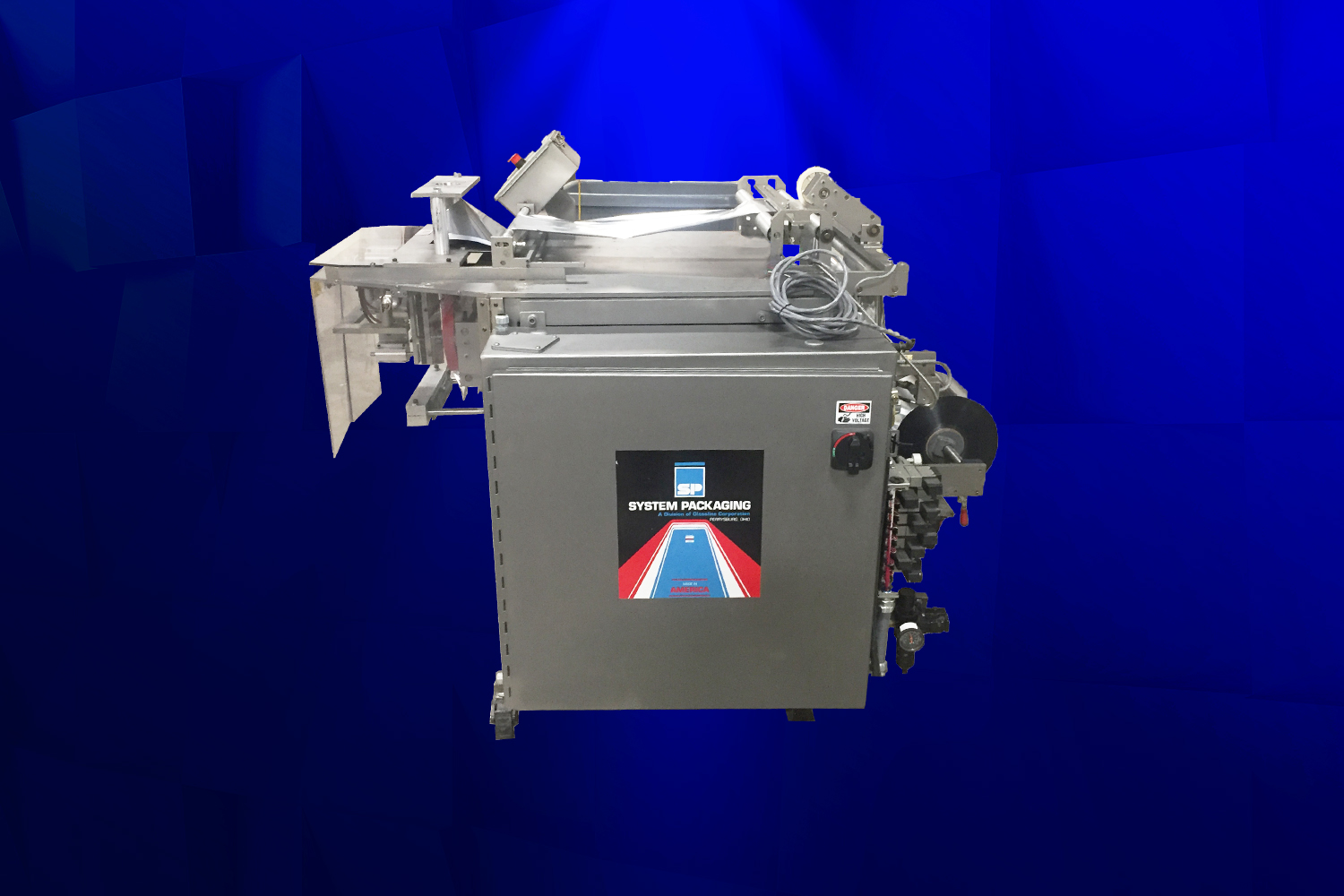

Model 1300 Poly Tubing Bagging Machine

Machine Specifications:

- Standard 3″ to 12″ package width and 3″ to 20″ package lengths. Modifications can run exponentially longer lengths.

- Dial-in length control system lets operator vary bag length in 1/10″ increments throughout the range of the machine

- Designed to use low cost 2 to 4 mil polyethylene tubing

- Fully automatic operation with adjustable dwell time

- Utilizes either PLAIN or Pre-Printed Poly Tube Stock

Machinery Options:

- Electric eye cut-off for registered, printed tubing

- Hot stamp imprinter (codes, dates, part numbers)

- Incline exit conveyor

- Indexing infeed bucket conveyor

- Hole punch

- Casters

- Automatic vibratory electronic counting equipment

- Pre-set batch counter for running a specified amount of bags with automatic shutoff

- Automatic weighing systems

- Volumetric Fillers

Have any questions? Feel free to reach out to one of our experts.