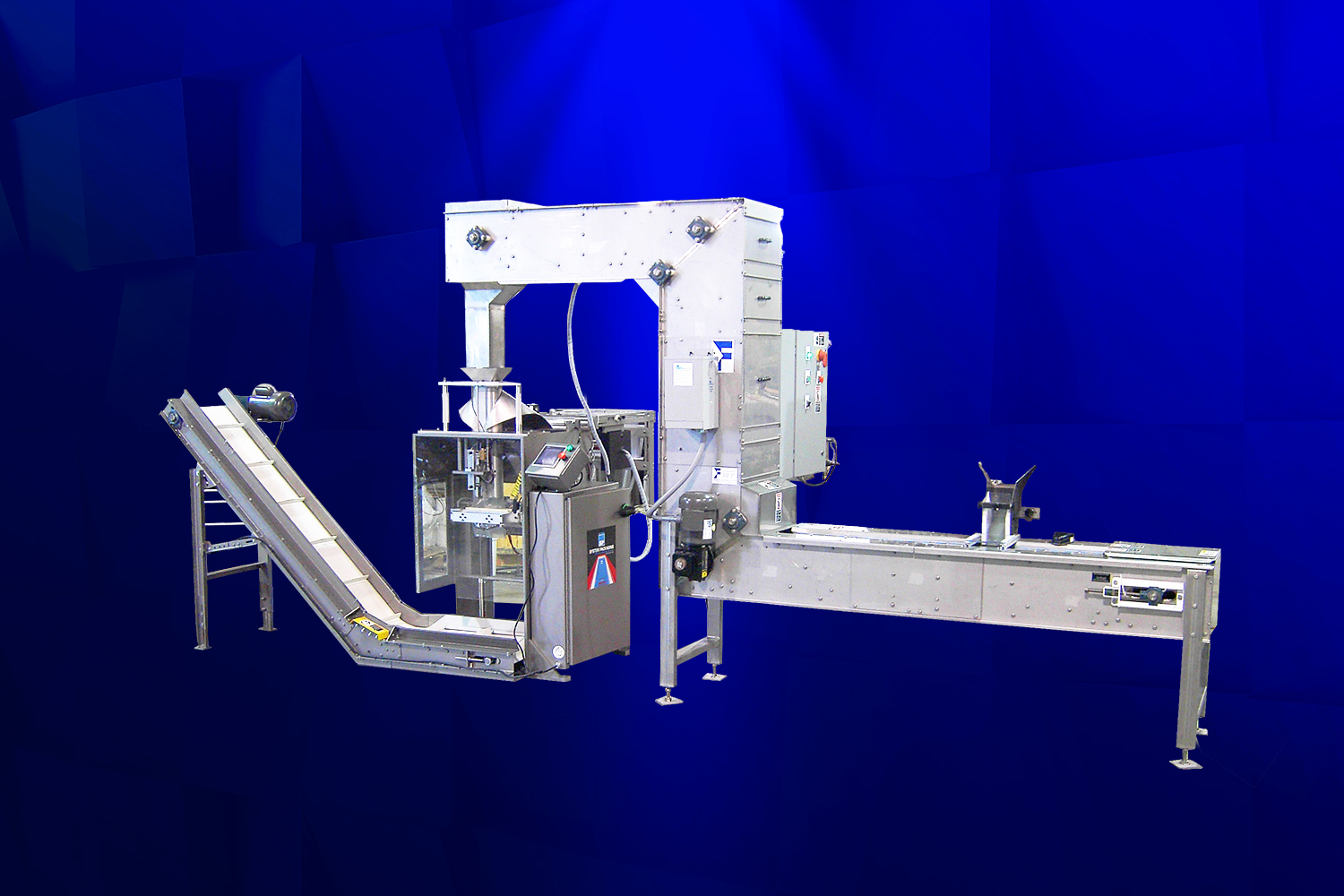

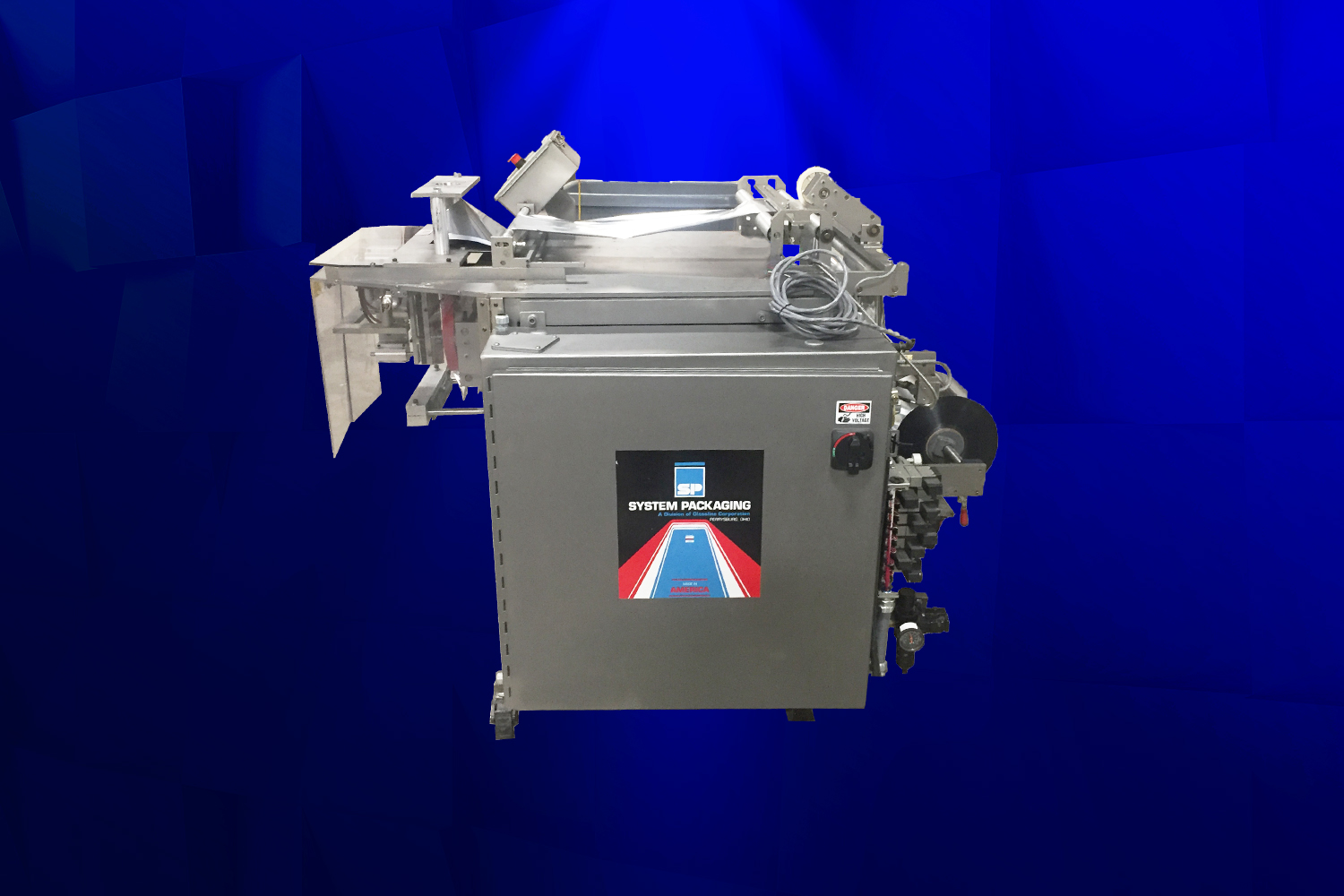

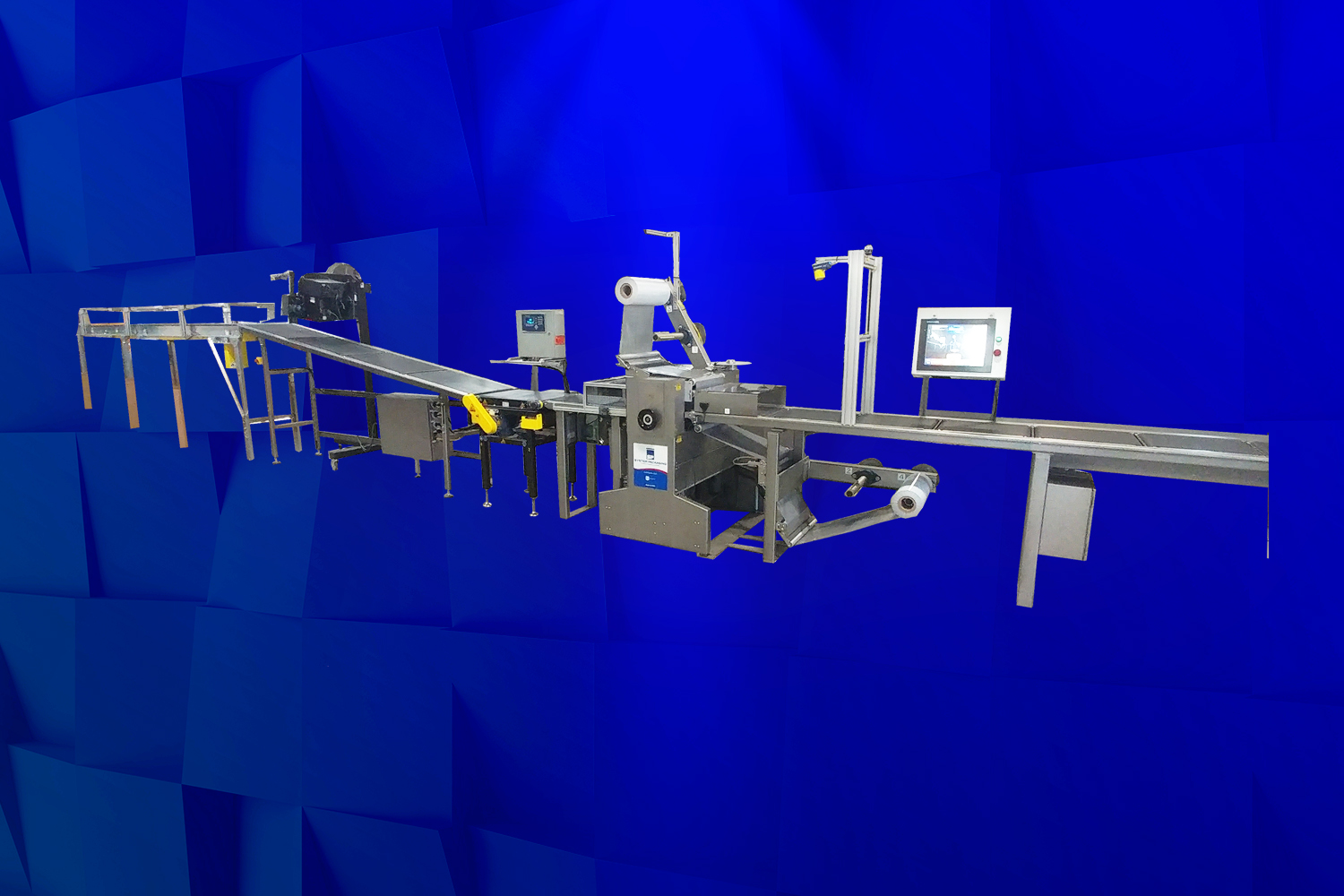

Model CH 1800 Horizontal Heat Seal Pouch Machine

Machine Specifications:

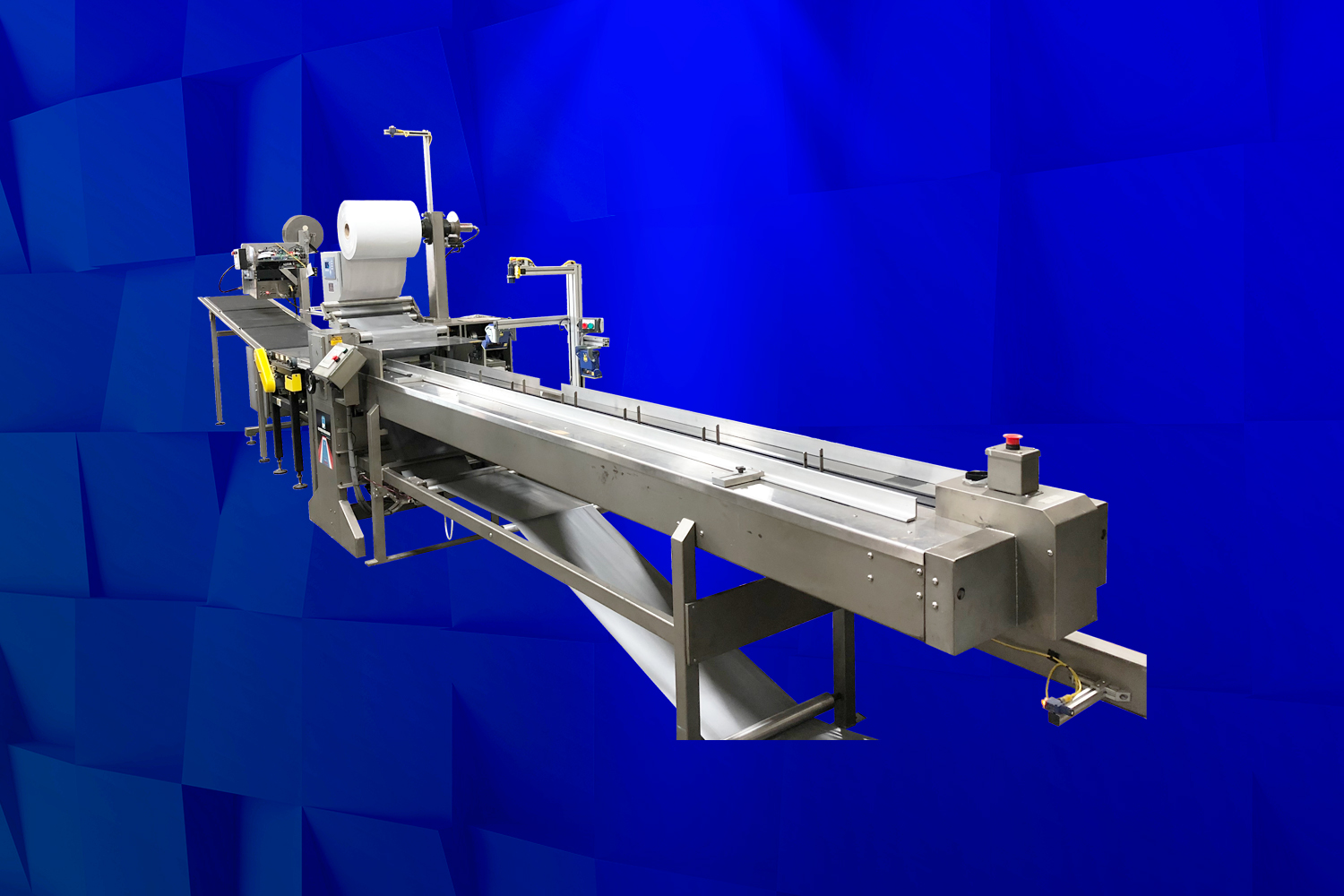

- This machine uses two rolls of strip coated bubble or polyethylene

- The CH1800 measures the length of the product and makes a package accordingly

- The standard system comes with a flited/lugged infeed conveyor

- The side seals and length cutoff are done simultaneously in the sealing head of the system

- Machine operation and setup are done through the touch screen controller

- Pneumatic spindle for a quick material change

- The system is available in 18″ and 24″ wide models

- The maximum width and height through the machine varies upon the model

- The CH1800 has a 5″ high package capability

- The 600-18 has a 6″ hgh package capability

- The CH2400 gas a 8″ high package capability

- It uses 220-440 V.A.C. and 80 PSI

- The units can run up to 15 to 20 packages per minute

Machine options include, but are not limited to the following:

- Print and apply label applicators

- Tape applicator for reclose able packages

- Perforators for easy open packages

- Inline package sortation systems

- Barcode/verify scanners

- Wider spaced flite sections for larger products

- Inline weighing and manifesting

- Printers/inserts for packing slips and/or return labels

- Friction feeders for automatic collating

Features:

- CH-1800 Standard 18” maximum width and 5” maximum height

- CH-2400 Standard 24” maximum width and 8” maximum height

- 8’ Stainless Steel Flited Infeed Conveyor

- 3’ Exit Conveyor

- Touch Screen Operator Control Panel

- Powered Width Adjustments

- Nema 12 Electrical Enclosure

- No special ventilation problems

- Random length control system lets operator vary package length on the fly for most economy of material

Material Substrates That Can Be Run On

- All of the material has to be cohesive coating.

Have any questions? Feel free to reach out to one of our experts.